This product adopts a variable frequency winding design, ensuring the motor's smooth conversion operation between 1HZ and 50HZ for a long time. This innovative design not only saves energy and prolongs service life, but also provides lasting and reliable performance in the work process. Whether in a home or industrial environment, this product will provide users with excellent efficiency and reliability, making it an indispensable tool in the manufacturing and production process.

1, Netzteil: trije-fase AC 380V (tolerânsje + / - 5%), 50HZ (tolerânsje + / - 1%).

2, wetterkwaliteit:

(1) water temperature is not higher than 20 °C;

(2) fêste ûnreinheden ynhâld (massa ratio) is net grutter as 0,01%;

(3) PH wearde (pH) 6,5-8,5;

(4) wetterstof sulfide ynhâld is net grutter as 1.5mg / L;

(5) chloride ion ynhâld is net grutter as 400mg / L.

3, de motor is sletten of mei wetter fol wiete struktuer, foardat gebrûk de ûnderdompele motor holte moat wêze fol mei skjin wetter, foar te kommen falske fol, en dan strak it wetter ynjeksje, lucht release bouten, oars net tastien te brûken

4, submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m. 5, the well water flow should be able to meet the submersible pump water output and continuous operation, the submersible pump water output should be controlled at 0.7 - 1.2 times the rated flow.

6, de put moat rjocht wêze, de dompelpomp kin net brûkt wurde of dumpt, allinich fertikaal gebrûk.

7, de dompelpomp moat wurde matched mei de kabel neffens de easken, en de eksterne overload beskerming apparaat.

8, de pomp is strang ferbean sûnder wetter no-load test masine

| Model | Flow (m3/h) | Holle (m) |

Rotatingspeed (feroarje/punt) |

Wetterpomp(%) | Outlet diameter (mm) |

Goed tapast diameter (mm) |

Rated power(KW) |

Rated spanning (V) |

Rated aktuele (A) |

Motor effisjinsje (%) | power factorcosφ | Ienheid Radiale Maksimum grutte (mm) |

Opmerking | |||||||||

| 300QJ200-40 | 200 | 40 | 2900 | 76 | 150 | 300boppe | 37 | 380 | 77.8 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ200-60 | 60 | 55 | 115 | 85.5 | 0.85 | |||||||||||||||||

| 300QJ200-80 | 80 | 75 | 154.1 | 86.0 | 0.86 | |||||||||||||||||

| 300QJ200-100 | 100 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-120 | 120 | 100 | 204.3 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ200-160 | 160 | 140 | 277.8 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-180 | 180 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-200 | 200 | 185 | 367.2 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-240 | 240 | 220 | 436.6 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ320-30 | 320 | 30 | 2900 | 77 | 200 | 300boppe | 45 | 380 | 94.6 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ320-60 | 60 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ320-90 | 90 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ320-120 | 120 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

This well submersible pump is a pump suitable for clean water. It is strictly prohibited to dig new wells and pump dirty water containing sediment. The voltage grade of the pump is 380/50HZ, and other submersible motors with different voltage grades need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as short circuit overload protection, dephase protection, undervoltage protection, grounding protection and idling protection, etc., in order to prevent timely tripping when abnormal conditions occur. During the installation and use process, the pump must have reliable grounding. It is strictly prohibited to push and pull the switch when your hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. An obvious sign "anti-electric shock" must be set up where the pump is used. Before going down the well or installation, the motor must be filled with distilled water or non-corrosive clean cold water, and the water inlet and outlet bolts must be tightened. When testing the pump on the ground, water must be filled into the pump chamber to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the steering is correct. Pay attention to safety when the pump is upright to prevent toppling and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump with a large flow at low lift or produce a large pull at high lift, resulting in extreme wear of thrust bearings and other parts, the motor overload and burn. After the pump into the well, the measurement of the motor to the ground insulation resistance should not be less than 100MΩ. After starting, regularly observe the voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage temperature below freezing point, should be drained to prevent the water in the motor cavity from freezing and cause the motor damage due to low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components.

De wichtichste skaaimerken fan it produkt binne:

- 1.The motor is a water-filled wet submersible three-phase asynchronous motor. The motor cavity is filled with clean water, used to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water in the body caused by the temperature rise of the motor.

- 2. In order to prevent the sand particles from entering the motor, two sand seals are installed at the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring.

- 3. In order to prevent the pump shaft from jumping when starting, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed at the bottom of the motor.

- 4. The lubrication method of the motor and the pump bearing is water lubrication.

- 5. The stator winding of the motor adopts high quality submersible motor winding wire with high insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Tarieding foar ynstallaasje:

1. Kontrolearje oft de dompelpomp foldocht oan de gebrûksbetingsten en omfang spesifisearre yn 'e hantlieding.

2. Mei in swiere objekt mei in diameter lyk oan de maksimale bûtendiameter fan 'e dompelpomp, mjitte oft de binnendiameter fan' e putboring de dompelpomp passe kin, en mjit oft de putdjipte foldocht oan de ynstallaasjeeasken.

3. Kontrolearje oft de putboring skjin is en oft it putwetter troebel is. Nea brûke in dompelpomp elektryske pomp te waskjen de welor pomp modder en sân wetter te kommen foar betiid skea oan de dompelpomp elektryske pomp.

4. Kontrolearje oft de posysje fan de welhead ynstallaasje clamp is geskikt en oft it kin wjerstean de kwaliteit fan de hiele ienheid

5. Kontrolearje oft de submersible pomp ûnderdielen binne kompleet en ynstallearre goed neffens de gearstalling diagram yn de hânlieding Ferwiderje it filter skerm en draaie de koppeling om te sjen oft it draait fleksibel

6. Skroef de wetterskroef los en folje de motorholte mei skjin, net-korrosyf wetter (notysje. Wês wis dat it opfolje), dan draait de wetterskroef oan. Nei 12 oeren fan wetterynjeksje moat de isolaasjeferset fan 'e motor net minder wêze dan 150M Q as mjitten mei in 500V skoddetafel.

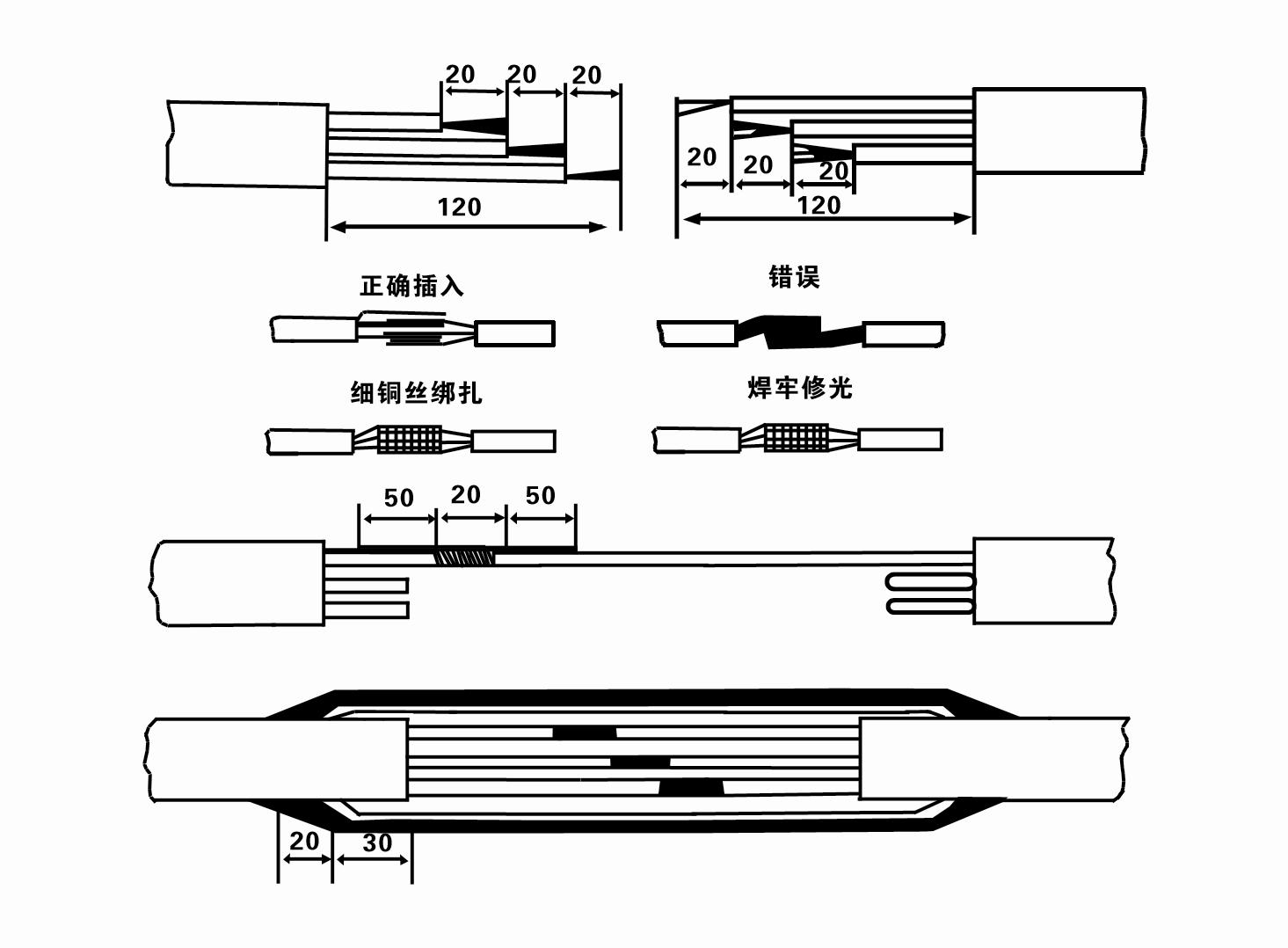

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

It taheakke prosesdiagram foar kabelbedrading is as folget:

8. Brûk in multimeter om te kontrolearjen oft de trije-fase triedden binne ferbûn en oft de DC ferset is likernôch lykwichtich.

9. Kontrolearje oft it circuit en transformator kapasiteit binne oerladen, en dan ferbinen de oerlêst beskerming switch of begjinnende apparatuer. Sjoch Tabel 2 foar spesifike modellen, en dan Giet in amer mei wetter yn 'e wetterpomp út' e wetterpompútlaat om de rubberlagers yn 'e pomp te smeerjen, en set dan de ûnderdompelbere elektryske pomp rjochtop en steady.Start (net mear as ien sekonde) en kontrolearje oft de stjoerrjochting oerienkomt mei it stjoerteken. As net, ruilje alle twa Anschlüsse fan 'e trije-faze kabel. Ynstallearje dan it filter en meitsje jo klear om de put del te gean. As brûkt by spesjale gelegenheden (lykas sleatten, sleatten, rivieren, fivers, fivers, ensfh.), De elektryske pomp moat betrouber wurde grûn.

(2) Ynstallaasje apparatuer en ark:

1. Ien pear liftkeatlingen foar mear as twa ton.

2. In tripod mei in fertikale hichte fan net minder as fjouwer meter.

3. Twa hingjende touwen (wire touwen) dy't in gewicht fan mear as ien ton drage kinne (kinne it gewicht fan in folsleine set wetterpompen drage).

4. Ynstallearje twa pearen fan clamps (spalken).

5. Wrenches, hammers, schroevendraaiers, elektryske ark en ynstruminten, ensfh.

(3) Elektryske pomp ynstallaasje:

1. It ynstallaasjediagram fan 'e ûnderdompele elektryske pomp wurdt werjûn yn figuer 2. De spesifike ynstallaasjedimensjes wurde werjûn yn Tabel 3 "List fan ynstallaasje-ôfmjittings fan 'e ûnderdompele elektryske pomp".

2. Submersible elektryske pompen mei in kop minder as 30 meter kinne direkt yn 'e boarne ophelle wurde mei slangen en draadseilen of oare himp-touwen dy't it folsleine gewicht fan' e hiele masine, wetterpipes, en wetter yn 'e pipes drage kinne.

3. Pompen mei in kop fan mear as 30 meter brûke stielen pipen, en de ynstallaasje folchoarder is as folget:

①Gebrûk in klem om it boppeste ein fan it wetterpompdiel te klemmen (de motor en de wetterpomp binne op dit stuit ferbûn), til it mei in hingjende keatling op en bine it stadichoan yn 'e put oant Set de klem op' e putkop en fuortsmite hingjende ketting.

② Brûk in oar pear klemmen om in piip te klemmen, til it mei in hingjende ketting 15 sm fuort fan 'e flange, en ferleegje it stadich. Tusken pipe flange en pomp flangePut de rubberen pad yn plak en strak de piip en pomp gelyk mei bouten, moeren en spring washers.

③ Til de dompelpomp in bytsje op, ferwiderje de klem op 'e boppeste ein fan' e wetterpomp, bine de kabel stevich oan 'e wetterpipe mei in plestik tape, en bûgje it stadichoan oant De klem wurdt pleatst by de putkop.

④Brûk deselde metoade om alle wetterpipes yn 'e put te binen.

⑤ Neidat de lead-out kabel is ferbûn mei de kontrôle switch, it is ferbûn oan de trije-fase Netzteil.

(4) Dingen om op te merken by ynstallaasje:

1. As in jamming ferskynsel wurdt fûn tidens it pompen proses, draaie of lûke de wetter piip te oerwinnen it jamming punt. As ferskate maatregels noch net wurkje, twinge asjebleaft de pomp net omleech om skea oan 'e dompelpomp en de put te foarkommen.

2. By ynstallaasje moat in rubberen pad op 'e flange fan elke piip pleatst wurde en gelijkmatig oanskerpe.

3. As de wetterpomp yn 'e boarne ferlege wurdt, moat it yn' e midden fan 'e putpipe pleatst wurde om te foarkommen dat de pomp lang tsjin' e wellmuorre rint, wêrtroch't de pomp trillet en de motor sweep en brânt .

4. Bepale de djipte fan 'e wetterpomp nei de boaiem fan' e boarne neffens de streamende sân- en siltbetingsten fan 'e boarne. Begrave de pomp net yn 'e modder. De ôfstân fan 'e wetterpomp nei de boaiem fan' e put is oer it generaal net minder as 3 meter (sjoch figuer 2).

5. De wetteryngongsdjipte fan 'e wetterpomp moat net minder wêze as 1-1,5 meter fan it dynamyske wetterpeil nei it wetteryntreeknooppunt (sjoch figuer 2). Oars kinne de wetterpomplagers maklik skea wurde.

6. De lift fan 'e wetterpomp kin net te leech wêze. Oars, in poarte fentyl moat wurde ynstallearre op de wellhead wetter pipeline te kontrolearjen de pomp trochstreaming op de rated flow punt om foar te kommen dat de motor wurdt oerladen en útbaarnd fanwege grutte stream tariven.

7. As de wetterpomp rint, moat de wetterútfier kontinuële en sels wêze, de aktuele moat stabyl wêze (ûnder beoardielde wurkomstannichheden, oer it generaal net mear as 10% fan 'e nominearre aktuele), en der moat gjin trilling of lûd wêze. As der in abnormaliteit is, moat de masine wurde stoppe om de oarsaak te finen en it te eliminearjen.

8. By it ynstallearjen, betelje omtinken oan de ynstelling fan 'e motor grûndraad (sjoch figuer 2). As it wetter piip is in stielen piip, liedt it út de puthead clamp; as it wetter piip is in plestik piip, liedt it út 'e grûn mark fan' e elektryske pomp.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon. If everything is normal, it can be put into operation.

- 2. After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing excessive motor current and burnout.

- 4.After the pump is running normally, in order to prolong its service life, it is necessary to check the power supply voltage, running current and insulation resistance regularly to see if they are normal.If the following conditions are found, the equipment should be shut down immediately to troubleshoot.

- (1)Under the rated working conditions, the current exceeds 20% of the rated value.

- (2)The dynamic water level drops to the inlet part, resulting in intermittent water discharge.

- (3)The submersible pump vibrates violently or emits noisy noise.

- (4)The power supply voltage is lower than 340 volts.

- (5)A fuse is burned out.

- (6)The water pipe is damaged.

- (7)The thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- These inspections will help to ensure the normal operation of the pump, improve its reliability and stability, so as to ensure its durability and service life.

- 5.unit disassembly:

- - untie cable rope, remove the pipeline part, remove the wire plate.

- - skroef de wetterbout del, set it wetter yn 'e motorkeamer.

- - remove the filter, loose the fixed screw on the coupling fixed motor shaft.

- - screw down the bolt connected with the motor at the inlet junction, separate the pump and the motor (pay attention to the unit cushion when separating, prevent the bending of the pump shaft)

- - pump disassembly sequence is: (see figure 1) inlet junction, impeller, guide housing, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, avoid bending the pump shaft and each part in the disassembly process.

- - motor disassembly process is: (see figure 1) place the motor on the platform, remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn, then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- - unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- 6.The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, set it wetter yn 'e motorholte (benammen yn' e winter om foar te kommen dat de motor befriest), en bine de kabel goed.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, lange-termyn gebrûk moatte betelje omtinken foar de roest previnsje fan dompelpompen.

- Impeller

- Shaft mouwe

- Rubber shaft sleeve

-

Segelring

01 Djippe boarne wetter yntak

02 Hege wetterfoarsjenning

03 berch wetterfoarsjenning

04 toer wetter

05 Agraryske yrrigaasje

06 tún yrrigaasje

07 rivier wetter yntak

08 húshâldlik wetter