This product adopts a variable frequency winding design, ensuring the motor's smooth conversion operation between 1HZ and 50HZ for a long time. This innovative design not only saves energy and prolongs service life, but also provides lasting and reliable performance in the work process. Whether in a home or industrial environment, this product will provide users with excellent efficiency and reliability, making it an indispensable tool in the manufacturing and production process.

1, Korontada: saddex-waji AC 380V (dulqaad +/- 5%), 50HZ (dulqaad +/- 1%).

2, tayada biyaha:

(1) water temperature is not higher than 20 °C;

(2) Waxyaabaha wasakhda adag ku jira (samiga baaxadda) kama badna 0.01%;

(3) Qiimaha PH (pH) 6.5-8.5;

(4) Waxa ku jira hydrogen sulfide kama badna 1.5mg/L;

(5) Waxa ku jira chloride ion kama badna 400mg/L.

3, matoorku waa xiran yahay ama qaab-dhismeedka qoyan ee biyaha ka buuxsamay, ka hor inta aan la isticmaalin godka matoorka submersible waa in ay ka buuxaan biyo nadiif ah, si looga hortago been buuxda, ka dibna adkeeyo duritaanka biyaha, boolal sii daayo hawada, haddii kale loo ogol yahay in la isticmaalo.

4, submersible pump must be completely submerged in the water, the diving depth is not greater than 70m, the bottom of the submersible pump from the bottom of the well is not less than 3m. 5, the well water flow should be able to meet the submersible pump water output and continuous operation, the submersible pump water output should be controlled at 0.7 - 1.2 times the rated flow.

6, Ceelku waa inuu toosan yahay, bamka submersible lama isticmaali karo ama laguma daadin karo, kaliya isticmaal toosan.

7, bamka submersible waa in lagu dhejiyaa fiilada si waafaqsan shuruudaha, iyo qalabka ilaalinta xad-dhaafka ah ee dibadda.

8, bamka si adag ayaa loo mamnuucay iyada oo aan jirin mishiinka tijaabada ah ee wax-load ah

| Qaabka | Socodka (m3/saacaddii) | Madaxa (m) |

Xawaaraha wareega (isbeddel/dhibic) |

Biyo-mareenka (%) | Bixinta dhexroorka (mm) |

Si fiican loo dabaqi karo dhexroor (mm) |

Lagu qiimeeyay power(KW) |

Lagu qiimeeyay danab (V) |

Lagu qiimeeyay hadda (A) |

Karti (%) | power factorcosφ | Unug Cabbirka Radial Maximu (mm) |

Odhaah | |||||||||

| 300QJ200-40 | 200 | 40 | 2900 | 76 | 150 | 300sare | 37 | 380 | 77.8 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ200-60 | 60 | 55 | 115 | 85.5 | 0.85 | |||||||||||||||||

| 300QJ200-80 | 80 | 75 | 154.1 | 86.0 | 0.86 | |||||||||||||||||

| 300QJ200-100 | 100 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-120 | 120 | 100 | 204.3 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ200-140 | 140 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ200-160 | 160 | 140 | 277.8 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-180 | 180 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-200 | 200 | 185 | 367.2 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ200-240 | 240 | 220 | 436.6 | 88.0 | 0.87 | |||||||||||||||||

| 300QJ320-30 | 320 | 30 | 2900 | 77 | 200 | 300sare | 45 | 380 | 94.6 | 85.0 | 0.85 | 281 | ||||||||||

| 300QJ320-60 | 60 | 90 | 183.8 | 86.5 | 0.86 | |||||||||||||||||

| 300QJ320-90 | 90 | 125 | 249.5 | 87.5 | 0.87 | |||||||||||||||||

| 300QJ320-120 | 120 | 160 | 317.5 | 88.0 | 0.87 | |||||||||||||||||

This well submersible pump is a pump suitable for clean water. It is strictly prohibited to dig new wells and pump dirty water containing sediment. The voltage grade of the pump is 380/50HZ, and other submersible motors with different voltage grades need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution boxes, etc. The starting equipment should have common comprehensive motor protection functions, such as short circuit overload protection, dephase protection, undervoltage protection, grounding protection and idling protection, etc., in order to prevent timely tripping when abnormal conditions occur. During the installation and use process, the pump must have reliable grounding. It is strictly prohibited to push and pull the switch when your hands and feet are wet. The power supply must be cut off before installation and maintenance of the pump. An obvious sign "anti-electric shock" must be set up where the pump is used. Before going down the well or installation, the motor must be filled with distilled water or non-corrosive clean cold water, and the water inlet and outlet bolts must be tightened. When testing the pump on the ground, water must be filled into the pump chamber to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the steering is correct. Pay attention to safety when the pump is upright to prevent toppling and injury. Strictly in accordance with the provisions of the pump lift and flow range, to prevent the pump with a large flow at low lift or produce a large pull at high lift, resulting in extreme wear of thrust bearings and other parts, the motor overload and burn. After the pump into the well, the measurement of the motor to the ground insulation resistance should not be less than 100MΩ. After starting, regularly observe the voltage and current, and check whether the motor winding insulation meets the requirements; if the pump storage temperature below freezing point, should be drained to prevent the water in the motor cavity from freezing and cause the motor damage due to low temperature.

The pump part is mainly composed of pump shaft, impeller, shunt shell, rubber bearing, check valve body (optional) and other components. The motor part is mainly composed of base, pressure regulating diaphragm, thrust bearing, thrust plate, lower guide bearing seat, stator, rotor, upper guide bearing seat, sand ring, water inlet section, lead cable and other components.

Tilmaamaha ugu muhiimsan ee alaabta waxaa ka mid ah:

- 1.The motor is a water-filled wet submersible three-phase asynchronous motor. The motor cavity is filled with clean water, used to cool the motor and lubricate the bearing. The pressure regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference of the water in the body caused by the temperature rise of the motor.

- 2. In order to prevent the sand particles from entering the motor, two sand seals are installed at the upper end of the motor shaft extension, and a sand control structure is formed by installing the sand ring.

- 3. In order to prevent the pump shaft from jumping when starting, the pump shaft is connected with the motor shaft through a coupling, and the thrust bearing is installed at the bottom of the motor.

- 4. The lubrication method of the motor and the pump bearing is water lubrication.

- 5. The stator winding of the motor adopts high quality submersible motor winding wire with high insulation performance.

- 6. The pump is designed by computer CAD, with simple structure and excellent technical performance.

(1) Diyaarinta ka hor inta aan la rakibin:

1. Hubi in bamka hoos mara uu buuxiyo shuruudaha isticmaalka iyo baaxadda lagu sheegay buug-gacmeedka.

2. Adigoo isticmaalaya dhexroor culus oo leh dhexroor la mid ah dhexroorka dibadda ee ugu sarreeya ee bamka hoos mara, cabbir haddii dhexroorka ceelka ceelka uu ku habboon yahay bamka hoos mara, cabbirna haddii qoto-dheeraanta ceelku buuxinayo shuruudaha rakibidda.

3. Hubi in ceelka ceelku uu nadiif yahay iyo in biyuhu ceelku yihiin kuwo gurracan. Weligaa ha isticmaalin bam koronto oo hoos iman kara si aad u dhaqdo bamka weriyaha dhoobada iyo biyaha ciidda si aad uga fogaato dhaawac degdeg ah oo soo gaadha bamka korontadu hoos u dhigto.

4. Hubi in booska xajinaha welhead ku habboon yahay iyo haddii ay u adkeysan karto tayada unugga oo dhan

5. Hubi in qaybaha matoorka hoos u dhigi karaan ay dhammaystiran yihiin oo si sax ah loo rakibay si waafaqsan jaantuska kulanka ee buug-gacmeedka, ka saar shaashadda oo beddel isku-xidhka si aad u aragto inay si dabacsan u wareegayso.

6. Ka fur furka biyaha oo ka buuxi godka matoorka biyo nadiif ah oo aan daxalaysan (xusuusnow in aad buuxiso), ka bacdina adkee xadhigga biyaha. Ka dib 12 saacadood oo duritaanka biyaha ah, caabbinta dahaarka ee matoorku waa in aanu ka yarayn 150M Q marka lagu cabbiro miis gariir 500V ah.

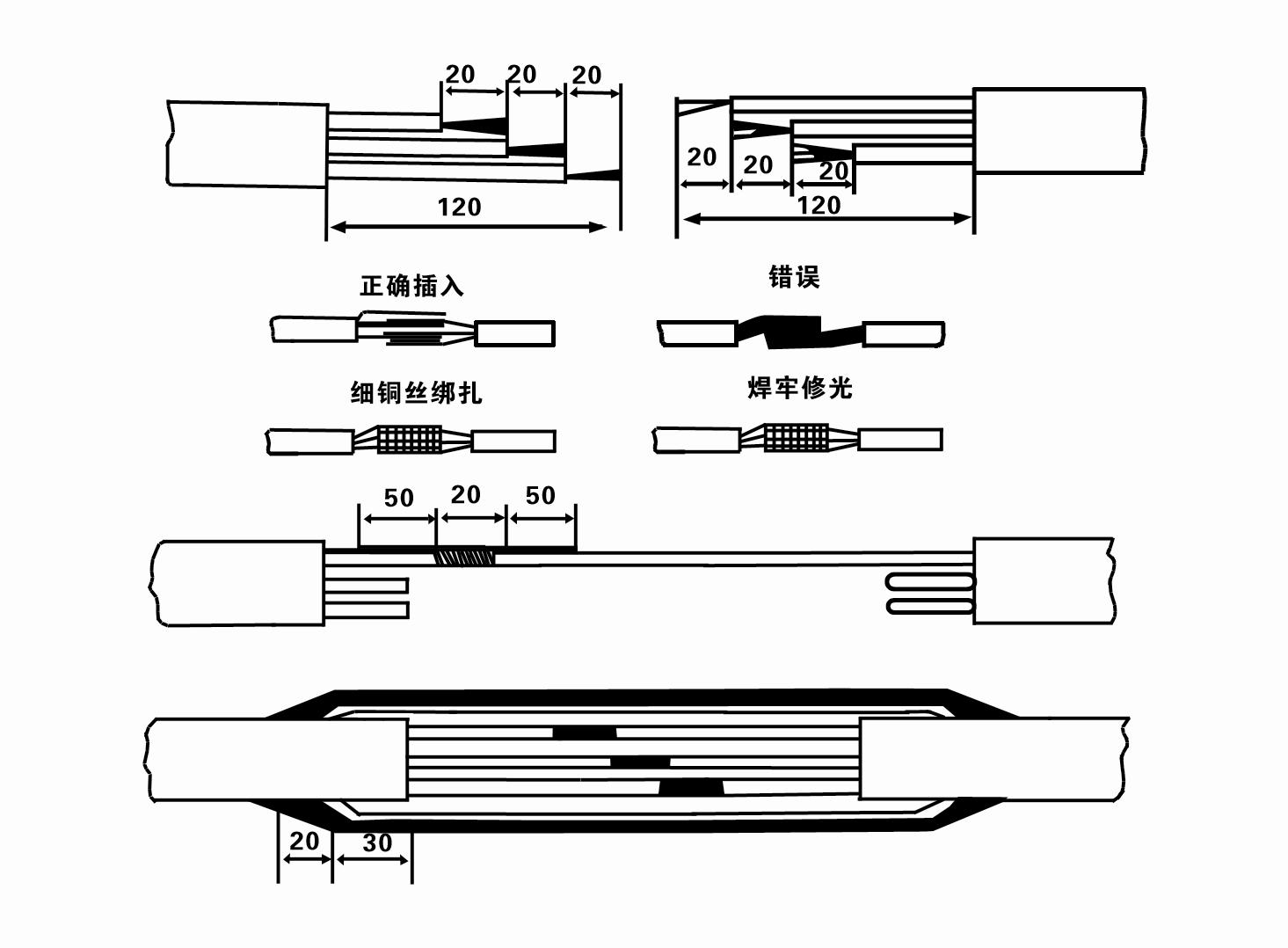

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Jaantuska habka fiilooyinka fiilooyinka ee ku lifaaqan waa sida soo socota:

8. Isticmaal multimeter-ka si aad u hubiso in xadhkaha saddexda weji ay isku xidhan yihiin iyo in iska caabbinta DC-ku ay qiyaas ahaan dheelli tiran yihiin.

9. Hubi in awoodda wareegga iyo beddelka ay si xad dhaaf ah u raran yihiin, ka dibna ku xidh furaha ilaalinta culayska ama qalabka bilowga. Ka eeg Shaxda 2 noocyo gaar ah, ka dibna ku shub baaldi biyo ah bamka biyaha ee ka soo baxa bamka biyaha si aad u saliidayn xadhkaha caagga ah ee bamka, ka dibna bamka korontadu hoos u dhigto dhig mid toosan oo joogto ah. Bilow (wax aan ka badnayn hal ilbiriqsi) oo hubi in jihada isteerinka ay waafaqsan tahay calaamadda isteerinka. Haddaysan ahayn, ku beddel laba xidhiidhiye oo ka mid ah fiilada saddexda weji leh. Kaddib rakib shaandhada una diyaari inaad ceelka dhaadhacdo. Haddii loo isticmaalo waqtiyo gaar ah (sida godadka, godadka, webiyada, balliyada, balliyada, iwm.), bamka korontadu waa in si la isku halleyn karo loo dejiyo.

(2) Qalabka iyo qalabka lagu rakibo:

1. Hal ka mid ah silsiladaha wax-qaadista ee ka badan laba tan.

2. Sadex geesood ah oo leh joog toosan oo aan ka yarayn afar mitir.

3. Laba xadhig oo ka laadlaad ah oo qaadi kara miisaan ka badan hal tan (waxay qaadi karaan culayska bambooyin biyo ah oo dhammaystiran).

4. Ku rakib laba-labo oo xajin ah (kabyo).

5. Biraha, dubbaha, kaashawiito, qalabka korontada iyo qalabka, iwm.

(3) Ku rakibida bamka korontada

1. Jaantuska rakibaadda ee bamka korontada hoostiisa ayaa lagu muujiyay Jaantuska 2. Cabbirrada rakibidda gaarka ah ayaa lagu muujiyay shaxda 3 "Liiska Cabbirrada Rakibaadda ee Bamka Korontada ee Submersible".

2. Bambooyin koronto oo hoos yimaada oo madax ka yar 30 mitir ayaa si toos ah loogu shubi karaa ceelka iyadoo la isticmaalayo tubooyinka iyo xargaha ama xargaha kale ee hemp kuwaas oo qaadi kara miisaanka buuxa ee dhammaan mishiinka, tuubooyinka biyaha, iyo biyaha tuubooyinka.

3. Bambooyin leh madax ka badan 30 mitir ayaa isticmaala tubooyinka birta, nidaamka rakibiddana waa sida soo socota.

①Isticmaal xajin si aad ugu xidho cidhifka sare ee qaybta matoorka biyaha (matoorka iyo bamka biyaha ayaa ku xidhan wakhtigan), ku qaad silsilad ka laadlaadsan, oo si tartiib ah ugu xidh ceelka ilaa aad xajinayso madaxa ceelka oo ka saar silsilad laadlaadsan.

② Isticmaal labo xajin oo kale si aad tuubada ugu xajiso, ku qaad silsilad laadlaad ah oo 15 cm ka fog garabka, oo si tartiib ah hoos ugu dhig. Inta u dhaxaysa flange tuubada iyo bamka bamka, dhig suufka caagga ah meesha oo adkee tuubada oo si siman ugu bamgareyso boolal, lawska iyo weelasha guga.

③ Xoogaa kor u qaad bamka hoos mara, ka saar xajinta cidhifka sare ee bamka biyaha, si adag ugu xidh fiilada tuubada biyaha cajalad balaastik ah, oo si tartiib ah hoos ugu xidh ilaa xajinta la dhigo madaxa ceelka.

④ Isticmaal isku qaab si aad ugu xidhid dhammaan tuubooyinka biyaha ceelka.

⑤Kadib markii fiilada macdanta "lead-out" lagu xiro furaha kantaroolka, waxay ku xiran tahay sahayda korontada ee saddexda weji.

(4) Waxyaabaha la xuso marka la rakibayo:

1. Haddi dhacdo isku buuqid ah la helo inta lagu jiro habka bamgareynta, leexi ama jiid tuubada biyaha si aad uga gudubto meesha saxmada leh. Haddii tillaabooyin kala duwani aanay weli shaqayn, fadlan ha ku qasbin bamka si aad uga fogaato burbur ku yimaadda bamka korontada ee hoos u dhigi kara iyo ceelka.

2. Inta lagu jiro rakibidda, suufka caagga ah waa in lagu dhejiyaa gees ka gees kasta oo tuubo ah oo la adkeeyo si siman.

3. Marka bamka biyaha lagu shubo ceelka waa in la dhex dhigaa dhuunta ceelka badhtankeeda si aanay bamku ugu socon darbiga ceelka muddo dheer, taasina ay keento in bamku gariiro oo matoorku xaaqo oo gubato. .

4. Go'aami qoto dheeraanta bamka biyaha ilaa gunta ceelka iyadoo loo eegayo ciidda qulqulaya iyo xaaladaha ciidda ee ceelka. Ha ku aasin bamka dhoobada. Masaafada u jirta bamka biyaha ilaa gunta ceelka guud ahaan waa mid aan ka yarayn 3 mitir (eeg sawirka 2).

5. Moolka gelitaanka biyaha ee bamka biyuhu waa in aanu ka yarayn 1-1.5 mitir heerka biyaha firfircoon ilaa marinka biyaha gelitaanka (eeg sawirka 2). Haddii kale, xadhkaha matoorka biyaha ayaa si fudud u dhaawacmi kara.

6. Wiishka bamka biyuhu ma noqon karo mid aad u hooseeya. Haddii kale, waxaa loo baahan yahay in lagu rakibo tuubada biyaha ee albaabka ceelka si loo xakameeyo socodka bamka ee barta socodka lagu qiimeeyay si looga hortago in matoorku uu si xad dhaaf ah u raro oo uu u gubto heerka socodka badan ee socodka awgeed.

7. Marka bamka biyuhu socdo, wax-soo-saarka biyuhu waa inuu ahaado mid joogto ah oo xitaa, hadda waa inuu ahaado mid deggan (marka la qiimeeyo xaaladaha shaqada, guud ahaan wax aan ka badnayn 10% ee hadda la qiimeeyay), waana inaysan jirin gariir ama buuq. Haddii ay jiraan wax aan caadi ahayn, mashiinka waa in la joojiyaa si loo ogaado sababta oo loo tirtiro.

8. Markaad rakibayso, fiiro gaar ah u yeelo goobta siliga goynta matoorka (eeg sawirka 2). Marka dhuumaha biyuhu ay yihiin tuubo bir ah, ka soo hoggaami xajinta madaxa ceelka; marka tuubada biyuhu ay tahay tuubo caag ah, ka soo jiid calaamadda dhulka ee bamka korontada.

- 1.After the submersible pump is installed, check the insulation resistance and three-phase conduction from the switch again, check whether the instrument and the connection of the start equipment are wrong, if there is no problem, the trial machine can be started, and observe whether the indicator readings of the instrument exceed the rated voltage and current specified on the nameplate after the start, and observe whether the pump has noise and vibration phenomenon. If everything is normal, it can be put into operation.

- 2. After the first operation of the pump for four hours, the motor should be shut down to test the thermal insulation resistance quickly, and its value should not be less than 0.5 megaohm.

- 3. After the pump is shut down, it should be started after five minutes to prevent the water column in the pipe from being completely reflowed and causing excessive motor current and burnout.

- 4.After the pump is running normally, in order to prolong its service life, it is necessary to check the power supply voltage, running current and insulation resistance regularly to see if they are normal.If the following conditions are found, the equipment should be shut down immediately to troubleshoot.

- (1)Under the rated working conditions, the current exceeds 20% of the rated value.

- (2)The dynamic water level drops to the inlet part, resulting in intermittent water discharge.

- (3)The submersible pump vibrates violently or emits noisy noise.

- (4)The power supply voltage is lower than 340 volts.

- (5)A fuse is burned out.

- (6)The water pipe is damaged.

- (7)The thermal insulation resistance of the motor to the ground is less than 0.5 megaohm.

- These inspections will help to ensure the normal operation of the pump, improve its reliability and stability, so as to ensure its durability and service life.

- 5.unit disassembly:

- - untie cable rope, remove the pipeline part, remove the wire plate.

- - Marooji boodhka biyaha, biyaha geli qolka matoorka.

- - remove the filter, loose the fixed screw on the coupling fixed motor shaft.

- - screw down the bolt connected with the motor at the inlet junction, separate the pump and the motor (pay attention to the unit cushion when separating, prevent the bending of the pump shaft)

- - pump disassembly sequence is: (see figure 1) inlet junction, impeller, guide housing, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, avoid bending the pump shaft and each part in the disassembly process.

- - motor disassembly process is: (see figure 1) place the motor on the platform, remove the nut, base, shaft head lock nut, thrust plate, key, lower guide bearing seat, double head bolt from the bottom of the motor in turn, then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- - unit assembly: Before assembly, the rust and dirt of the parts should be cleaned, and the mating surfaces and fasteners should be coated with sealant. Then they should be assembled in the reverse order of disassembly (the up and down momentum of the motor shaft is about 1 mm after assembly). After assembly, the coupling should be flexible, and then the filter screen test machine.

- 6.The submersible pump should be dismantled and repaired according to Article 5 for each operation year, or less than one year, but the submersible time has reached two years, and the worn parts should be replaced.

1, dami biyaha godka matoorka (gaar ahaan xilliga jiilaalka si aad uga hortagto matoorku baraf), oo si fiican u xidh fiilada.

2, store in an indoor room without corrosive substances and gases, with a temperature below 40 °C.

3, isticmaalka muddada dheer waa in fiiro gaar ah u leh ka hortagga miridhku ee matoorada submersible.

- Impeller

- Shaft sleeve

- Gacan-gacmeedka caagga ah

-

giraanta xiridda

01 Qaadashada biyaha ceelka qoto dheer

02 Biyo-helid-sare

03 biyaha buuraha

04 munaaradaha biyaha

05 waraabka beeraha

06 waraabka beerta

07 qaadashada biyaha webiga

08 biyaha guriga