Frequency conversion winding design, ensure the motor in 1HZ-50HZ long-term stable conversion operation. Energy saving, longer service life.

1, elektrik üpjünçiligi: üç fazaly AC 380V (çydamlylyk + / - 5%), 50HZ (çydamlylyk + / - 1%).

2, suwuň hili:

(1) water temperature is not higher than 20 °C;

(2) gaty hapalaryň düzümi (köpçülik gatnaşygy) 0,01% -den köp däl;

(3) PH bahasy (pH) 6.5-8.5;

(4) wodorod sulfidiniň düzümi 1,5mg / L-den uly däl;

(5) hlorid ionynyň düzümi 400mg / L-den uly däl.

3, motor ýapyk ýa-da suwdan doldurylan çygly gurluş, suwa çümýän motor boşlugy arassa suwdan doly bolmaly, ýalňyş dolmazlygy üçin, soň bolsa suw sanjymyny, howa çykaryjy boltlary berkitmeli, ýogsam ulanmaga rugsat berilmeýär

4, suwa çümýän nasos doly suwa çümmeli, çümmek çuňlugy 70 metrden köp bolmaly däl, guýynyň düýbünden suwasty nasosyň düýbi 3 m-den az bolmaly däldir.

5, guýynyň suw akymy suwa çümýän nasos suwunyň çykarylyşyny we üznüksiz işlemegini üpjün etmeli, suwa çümýän nasos suwunyň çykarylyşy bahalandyrylan akymyň 0,7 - 1,2 esse gözegçilikde saklanmalydyr.

6, guýy göni bolmaly, suwa çümýän nasosy ulanyp ýa-da taşlap bolmaýar, diňe dik ulanylýar.

7, suwa çümýän nasos talaplara laýyklykda kabel we daşarky artykmaç ýük göteriji gorag enjamy bilen gabat gelmelidir. 8, nasos suwy ýüklemeýän synag enjamy bolmazdan düýbünden gadagan

| Model | Akym (m3 / sag) | Baş (m) |

Rotating speed(change/point) | Suw nasosy (%) | Çykyş diametri (mm) |

Gowy ulanylýar diametri (mm) |

Bahalandyryldy kuwwat (KW) |

Rated voltage(V) | Ratedcurrent(A) | Motorefficiency (%) | power factorcosφ | Bölüm Radial Maksimu ululygy (mm) |

Bellik | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125ýokarda | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125ýokarda | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125ýokarda | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125ýokarda | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125ýokarda | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125ýokarda | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125ýokarda | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125ýokarda | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

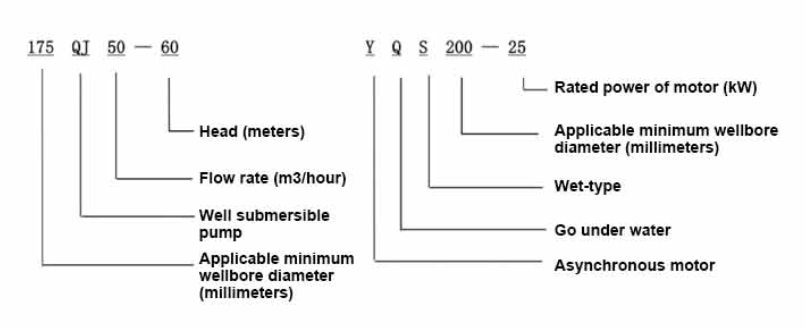

The well submersible pump is a pump suitable for clear water. It is strictly prohibited to dig new wells and pump out mud and sand. The voltage grade of the well pump is 380V/50HZ, and other voltage grades of the submersible motor need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protective device should be tripped in time. When installing and using the pump, it must be firmly grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power supply must be cut off before installing and maintaining the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing the motor, the inner cavity must be filled with distilled water or non-corrosive clean cold water, and the water injection/drainage bolts must be tightened. Fill the pump with water for ground test to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the direction is correct and consistent with the direction indication. Be sure to pay attention to safety when placing the pump upright to prevent overturning and causing injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump flow at low lift or excessive pull at high lift, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the insulation resistance between the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check the motor winding insulation, to see if it meets the requirements; if the pump storage temperature is below the freezing point, the water in the motor cavity should be discharged, so as to avoid the water in the motor cavity freezing and damaging the motor due to low temperature.

Önümiň esasy aýratynlyklary:

1.The motor is a water-loaded wet submersible three-phase asynchronous motor,and the motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference inside and outside the body caused by the temperature rise of the motor.

2.In order to prevent the sand particles in the well water from entering the motor,two oil seals are installed at the extension end of the motor shaft,and the sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from jumping when starting,the pump shaft is connected with the motor shaft through a coupling,and the thrust bearing is installed at the bottom of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The stator winding of the motor adopts high-quality submersible motor winding wire,with excellent insulation performance.

6.The pump is designed by computer CAD,with simple structure and excellent technical performance.

(1) Gurmakdan öň taýýarlyk:

1. Suwa çümýän nasosyň gollanmada görkezilen ulanyş şertlerine we gerimine laýyk gelýändigini barlaň.

2. Suwa çümýän nasosyň daşky diametrine deň bolan agyr obýekte ulanmak, guýynyň inneldiametriniň suwa çümýän nasosyna laýyk bolup biljekdigini ýa-da guýynyň çuňlugynyň gurnama talaplaryna laýyk gelýändigini ölçäň.

3. Guýynyň arassa bolandygyny ýa-da guýynyň suwunyň bulaşykdygyny barlaň. Suwa çümýän elektrik nasosyna wagtyndan öň zeper ýetmezligi üçin, garşylaýjy nasos palçyklaryny we gum suwlaryny ýuwmak üçin hiç wagt suwa çümýän elektrik nasosyny ulanmaň.

4. Kelleli gurnama gysgyjynyň ýagdaýynyň laýykdygyny ýa-da tutuş bölümiň hiline çydap biljekdigini barlaň

5. Gollanma gurnama diagrammasyna laýyklykda suwa çümýän nasos bölekleriniň doly we dogry gurlandygyny barlaň Süzgüç ekranyny aýyryň we çeýe aýlanýandygyny ýa-da ýokdugyny aýlaň.

6. Suw nurbatyny aýryň we motor boşlugyny arassa, poslamaýan suw bilen dolduryň (bellik ediň. 12 sagat suw sanjymyndan soň, 500V titreýän stol bilen ölçelende motoryň izolýasiýa garşylygy 150M Q-dan pes bolmaly däldir.

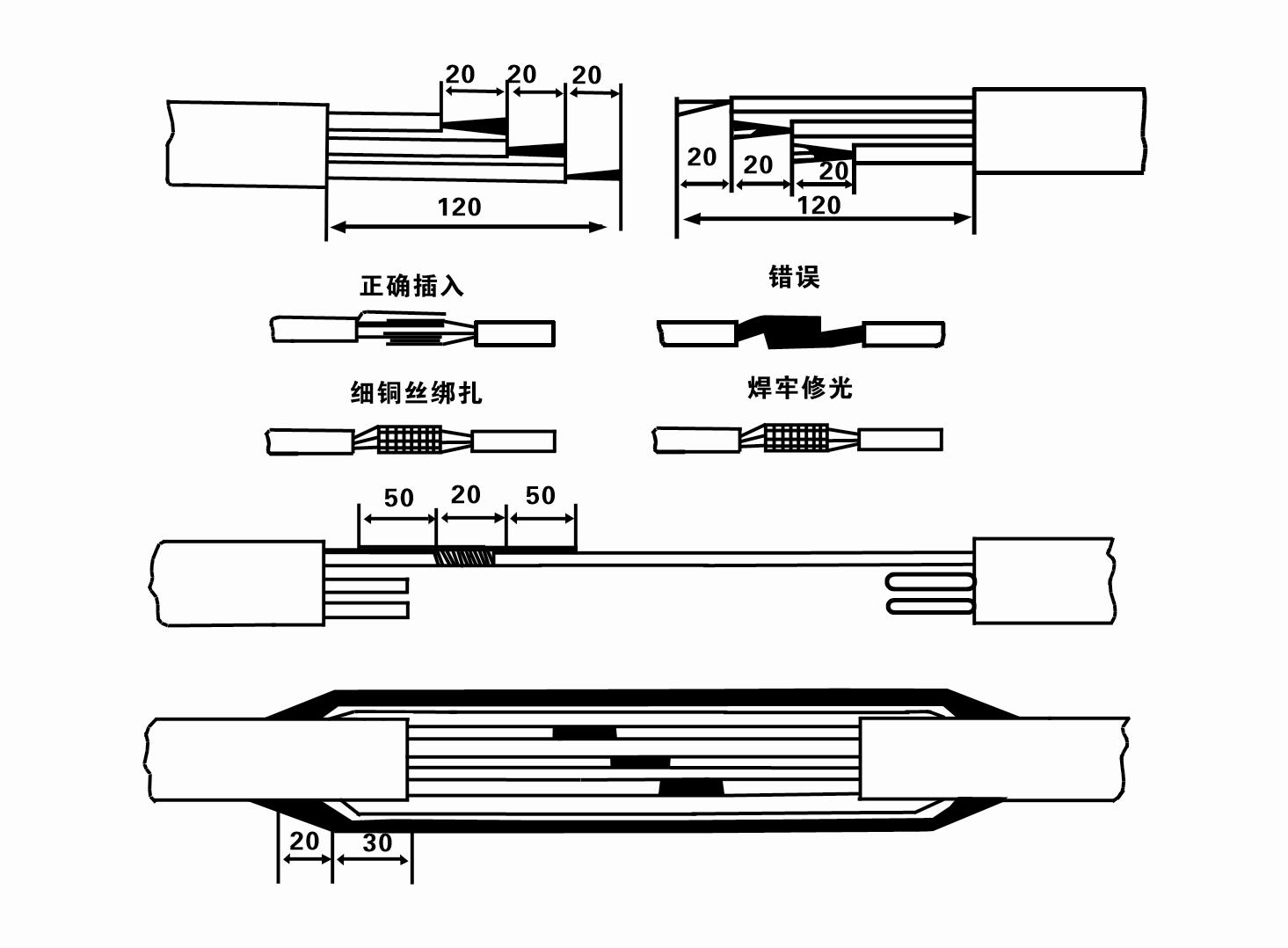

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.

After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Berkidilen kabel simleriniň diagrammasy aşakdaky ýaly:

8. Üç fazaly simleriň birikdirilendigini ýa-da DC garşylygynyň takmynan deňagramlydygyny ýa-da ýokdugyny barlamak üçin multimetr ulanyň.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and then

Pour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.

Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.

Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2) Gurnama enjamlary we gurallary:

1. Iki tonnadan gowrak göteriji zynjyr.

2. Dikligi dört metrden az bolmadyk üçburçluk.

3. Bir tonnadan gowrak agramy göterip bilýän iki sany asma ýüp (simli ýüpler) (suw nasoslarynyň doly toplumynyň agramyny göterip biler).

4. Iki jübüt gysgyç guruň.

5. Kirpikler, çekiçler, otwýortkalar, elektrik gurallary we gurallar we ş.m.

(3) Elektrik nasosyny oturtmak:

1. Suwa çümýän elektrik nasosynyň gurnama diagrammasy 2-nji suratda görkezilýär. Gurluşyň anyk ölçegleri 3-nji tablisada "Suwasty elektrik nasosynyň gurnama ölçegleriniň sanawy" görkezilýär.

2. Kellesi 30 metrden az bolan suwa çümdürilen elektrik nasoslary, ähli maşynyň, suw turbalarynyň we turbalardaky suwuň doly agramyny göterip bilýän şlanglar we sim arkanlary ýa-da beýleki kenep ýüpleri bilen göni guýa çykarylyp bilner.

3. 30 metrden gowrak kellesi bolan nasoslar polat turbalary ulanýarlar we gurnama yzygiderliligi aşakdaky ýaly:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well until

Put the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flange

Put the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

Sub Çökýän nasosy birneme ýokaryk galdyryň, suw nasosynyň ýokarky ujundaky gysgyçlary aýyryň, kabeli suw turbasyna plastmassa lenta bilen berkidiň we gysgyç guýynyň başyna goýulýança ýuwaş-ýuwaşdan daňyň.

Water waterhli suw turbalaryny guýa baglamak üçin şol bir usuly ulanyň.

Lead Gurluş kabeli dolandyryş wyklýuçateline birikdirilenden soň, üç fazaly elektrik üpjünçiligine birikdirilýär.

(4) Gurmak wagtynda bellemeli zatlar:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, please

Do not force the pump down to avoid damage to the submersible electric pump and the well.

2. Gurmak wagtynda her turbanyň flanesine rezin pad goýulmaly we deň derejede berkidilmeli.

3. Suw nasosy guýa düşürilende, nasosyň titremegine we motoryň süpürilmegine we ýanmagyna sebäp bolup, nasosyň guýynyň diwaryna uzak wagtlap işlemezligi üçin guýynyň turbasynyň ortasyna goýulmalydyr. .

4. Guýynyň akýan çäge we palçyk şertlerine görä guýynyň düýbüne suw nasosynyň çuňlugyny kesgitläň. Nasosy palçykda jaýlamaň. Suw nasosyndan guýynyň düýbüne çenli aralyk, adatça, 3 metrden az däl (2-nji surata serediň).

5. Suw nasosynyň suw giriş çuňlugy dinamiki suw derejesinden suw girelgesine çenli 1-1,5 metrden az bolmaly däldir (2-nji surata serediň). Otherwiseogsam, suw nasosynyň podşipnikleri aňsat zaýalanmagy mümkin.

6. Suw nasosynyň göterilmegi gaty pes bolup bilmez. Otherwiseogsam, uly akym tizligi sebäpli motoryň aşa köp ýüklenmeginiň we ýanmagynyň öňüni almak üçin, kesgitlenen akym nokadyndaky nasos akymyna gözegçilik etmek üçin guýy suw geçirijisine derwezeli klapan oturdylmalydyr.

7. Suw nasosy işleýän mahaly, suw çykarylyşy üznüksiz bolmaly we hatda tok durnukly bolmaly (bahalandyrylan iş şertlerinde, adatça bahalandyrylan tokyň 10% -inden köp bolmaly däldir) we yrgyldy ýa-da ses bolmaly däldir. Anormallik bar bolsa, sebäbini bilmek we ýok etmek üçin enjamy saklamaly.

8. Gurnanyňyzda, hereketlendirijiniň toprak siminiň sazlanmagyna üns beriň (2-nji surata serediň). Suw turbasy polat turba bolanda, ony guýy gysgyjyndan alyp gidiň; suw turbasy plastik turba bolanda, ony elektrik nasosynyň toprak belgisinden alyp çykyň.

- 1. Suwa çümdüriji nasos gurlansoň, wyklýuçatelden izolýasiýa garşylygyny we üç fazaly geçirijini täzeden barlaň, guralyň we başlangyç enjamyň birikmesiniň nädogrydygyny barlaň, kynçylyk ýok bolsa synag enjamy başlap biler, we guralyň görkezijileriniň okalmagy, başlandan soň at ýazgysynda görkezilen naprýatageeniýeden we tokdan ýokarydygyny ýa-da nasosyň ses we yrgyldy hadysasynyň bardygyny ýa-da ýokdugyny synlaň we hemme zat kadaly bolsa işe giriziň.

- 2. Nasos dört sagatlap ilkinji gezek işledilenden soň, ýylylyk izolýasiýa garşylygyny çalt barlamak üçin motor ýapylmaly we bahasy 0,5 megaohmdan pes bolmaly däldir.

- 3. Nasos ýapylansoň, turbadaky suw sütüniniň doly şöhlelenmeginiň we hereketlendirijiniň aşa köp tok we ýanmagyna sebäp bolmazlygy üçin bäş minutdan soň başlamaly.

- 4. Nasos kadaly işe girizilenden soň, hyzmat möhletini uzaltmak üçin üpjünçilik naprýa .eniýesiniň, işleýän tok we izolýasiýa garşylygynyň kadalydygyny ýa-da ýokdugyny barlamaly. Aşakdaky şertler tapylsa, näsazlyklary düzetmek üçin nasos derrew ýapylmalydyr.

- 1 In the rated condition, the current exceeds 20%.

- 2 Dinamiki suw derejesi, aralyk suwuň döremegine sebäp bolup, suw giriş bölümine düşýär.

- 3 Suwa çümýän nasosda yrgyldy ýa-da ses bar.

- 4 Üpjünçilik naprýa .eniýesi 340 woltdan pesdir.

- Ereýän predohranitel ýakylýar.

- 6 Suw üpjünçiligi turbasyna zeper ýetdi.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1.Untie the cable tie, remove the pipeline part, and remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product is an efficient and durable submersible electric pump, suitable for a variety of environments and applications.In order to ensure the long-term use and stable performance of the product, we suggest that users pay special attention to drying the water in the motor cavity in winter to avoid freezing; in addition, the cable is coiled and tied, and properly stored in an environment without corrosive substances and gases, with a temperature below 40 °C. If the product is not used for a long time, attention should be paid to rust prevention treatment to ensure the life cycle and performance of the product.Whether for industrial use or for home use, this submersible electric pump can provide you with reliable pump service.

-

- Impeller

- Mil ýeňi

- Kauçuk ýeň

-

Möhür halkasy

01 Çuň guýynyň suwy

02 -okary gatly suw üpjünçiligi

03 dag suw üpjünçiligi

04 diň suwy

05 Oba hojalygyny suwarmak

06 bag suwaryş

07 derýa suwuny kabul etmek

08 içerki suw