Frequency conversion winding design, ensure the motor in 1HZ-50HZ long-term stable conversion operation. Energy saving, longer service life.

1, Netzteil: trije-fase AC 380V (tolerânsje + / - 5%), 50HZ (tolerânsje + / - 1%).

2, wetterkwaliteit:

(1) water temperature is not higher than 20 °C;

(2) fêste ûnreinheden ynhâld (massa ratio) is net grutter as 0,01%;

(3) PH wearde (pH) 6,5-8,5;

(4) wetterstof sulfide ynhâld is net grutter as 1.5mg / L;

(5) chloride ion ynhâld is net grutter as 400mg / L.

3, de motor is sletten of mei wetter fol wiete struktuer, foardat gebrûk de ûnderdompele motor holte moat wêze fol mei skjin wetter, foar te kommen falske fol, en dan strak it wetter ynjeksje, lucht release bouten, oars net tastien te brûken

4, dompelpomp moat folslein ûnderdompele wurde yn it wetter, de dûkdjipte is net grutter as 70m, de boaiem fan 'e dompelpomp fan' e boaiem fan 'e put is net minder as 3m.

5, de put wetter stream moat wêze kinne om te foldwaan oan de submersible pomp wetter útfier en trochgeande operaasje, de submersible pomp wetter útfier moat wurde regele op 0,7 - 1,2 kear de rated stream.

6, de put moat rjocht wêze, de dompelpomp kin net brûkt wurde of dumpt, allinich fertikaal gebrûk.

7, de dompelpomp moat wurde matched mei de kabel neffens de easken, en de eksterne overload beskerming apparaat. 8, de pomp is strang ferbean sûnder wetter no-load test masine

| Model | Flow (m3/h) | Holle (m) |

Rotating speed(change/point) | Wetterpomp(%) | Outlet diameter (mm) |

Goed tapast diameter (mm) |

Rated macht (KW) |

Rated voltage(V) | Ratedcurrent(A) | Motor effisjinsje (%) | power factorcosφ | Ienheid Radiale Maksimum grutte (mm) |

Opmerking | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125boppe | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125boppe | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125boppe | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125boppe | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125boppe | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125boppe | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125boppe | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125boppe | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

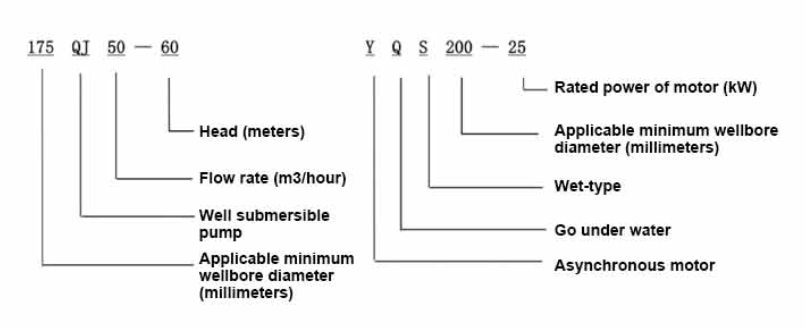

The well submersible pump is a pump suitable for clear water. It is strictly prohibited to dig new wells and pump out mud and sand. The voltage grade of the well pump is 380V/50HZ, and other voltage grades of the submersible motor need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protective device should be tripped in time. When installing and using the pump, it must be firmly grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power supply must be cut off before installing and maintaining the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing the motor, the inner cavity must be filled with distilled water or non-corrosive clean cold water, and the water injection/drainage bolts must be tightened. Fill the pump with water for ground test to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the direction is correct and consistent with the direction indication. Be sure to pay attention to safety when placing the pump upright to prevent overturning and causing injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump flow at low lift or excessive pull at high lift, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the insulation resistance between the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check the motor winding insulation, to see if it meets the requirements; if the pump storage temperature is below the freezing point, the water in the motor cavity should be discharged, so as to avoid the water in the motor cavity freezing and damaging the motor due to low temperature.

De wichtichste skaaimerken fan it produkt binne:

1.The motor is a water-loaded wet submersible three-phase asynchronous motor,and the motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference inside and outside the body caused by the temperature rise of the motor.

2.In order to prevent the sand particles in the well water from entering the motor,two oil seals are installed at the extension end of the motor shaft,and the sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from jumping when starting,the pump shaft is connected with the motor shaft through a coupling,and the thrust bearing is installed at the bottom of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The stator winding of the motor adopts high-quality submersible motor winding wire,with excellent insulation performance.

6.The pump is designed by computer CAD,with simple structure and excellent technical performance.

(1) Tarieding foar ynstallaasje:

1. Kontrolearje oft de dompelpomp foldocht oan de gebrûksbetingsten en omfang spesifisearre yn 'e hantlieding.

2. Mei in swiere objekt mei in diameter lyk oan de maksimale bûtendiameter fan 'e dompelpomp, mjitte oft de binnendiameter fan' e putboring de dompelpomp passe kin, en mjit oft de putdjipte foldocht oan de ynstallaasjeeasken.

3. Kontrolearje oft de putboring skjin is en oft it putwetter troebel is. Nea brûke in dompelpomp elektryske pomp te waskjen de welor pomp modder en sân wetter te kommen foar betiid skea oan de dompelpomp elektryske pomp.

4. Kontrolearje oft de posysje fan de welhead ynstallaasje clamp is geskikt en oft it kin wjerstean de kwaliteit fan de hiele ienheid

5. Kontrolearje oft de submersible pomp ûnderdielen binne kompleet en ynstallearre goed neffens de gearstalling diagram yn de hânlieding Ferwiderje it filter skerm en draaie de koppeling om te sjen oft it draait fleksibel

6. Skroef de wetterskroef los en folje de motorholte mei skjin, net-korrosyf wetter (notysje. Wês wis dat it opfolje), dan draait de wetterskroef oan. Nei 12 oeren fan wetterynjeksje moat de isolaasjeferset fan 'e motor net minder wêze dan 150M Q as mjitten mei in 500V skoddetafel.

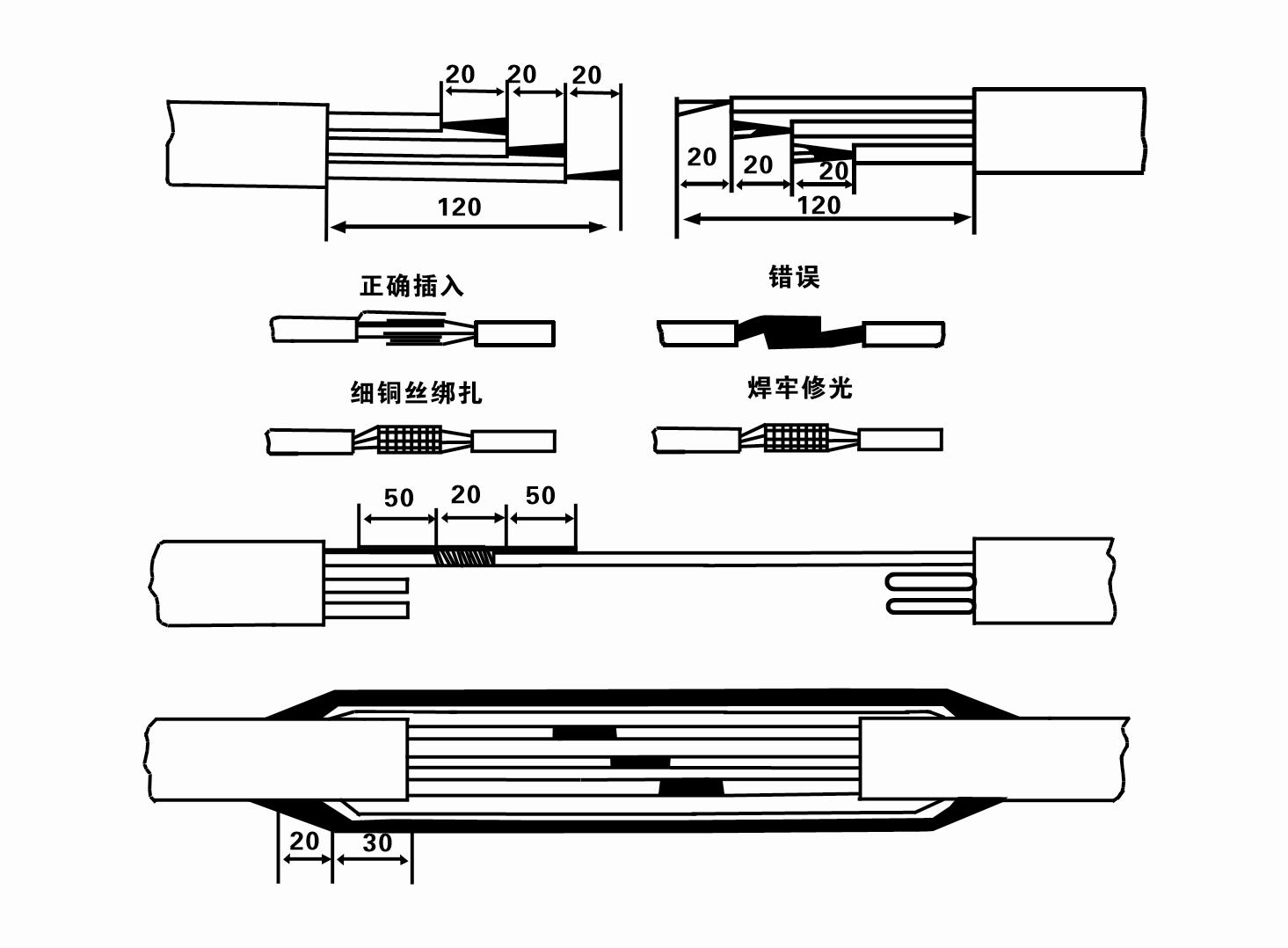

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.

After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

It taheakke prosesdiagram foar kabelbedrading is as folget:

8. Brûk in multimeter om te kontrolearjen oft de trije-fase triedden binne ferbûn en oft de DC ferset is likernôch lykwichtich.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and then

Pour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.

Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.

Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2) Ynstallaasje apparatuer en ark:

1. Ien pear liftkeatlingen foar mear as twa ton.

2. In tripod mei in fertikale hichte fan net minder as fjouwer meter.

3. Twa hingjende touwen (wire touwen) dy't in gewicht fan mear as ien ton drage kinne (kinne it gewicht fan in folsleine set wetterpompen drage).

4. Ynstallearje twa pearen fan clamps (spalken).

5. Wrenches, hammers, schroevendraaiers, elektryske ark en ynstruminten, ensfh.

(3) Elektryske pomp ynstallaasje:

1. It ynstallaasjediagram fan 'e ûnderdompele elektryske pomp wurdt werjûn yn figuer 2. De spesifike ynstallaasjedimensjes wurde werjûn yn Tabel 3 "List fan ynstallaasje-ôfmjittings fan 'e ûnderdompele elektryske pomp".

2. Submersible elektryske pompen mei in kop minder as 30 meter kinne direkt yn 'e boarne ophelle wurde mei slangen en draadseilen of oare himp-touwen dy't it folsleine gewicht fan' e hiele masine, wetterpipes, en wetter yn 'e pipes drage kinne.

3. Pompen mei in kop fan mear as 30 meter brûke stielen pipen, en de ynstallaasje folchoarder is as folget:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well until

Put the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flange

Put the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

③ Til de dompelpomp in bytsje op, ferwiderje de klem op 'e boppeste ein fan' e wetterpomp, bine de kabel stevich oan 'e wetterpipe mei in plestik tape, en bûgje it stadichoan oant De klem wurdt pleatst by de putkop.

④Brûk deselde metoade om alle wetterpipes yn 'e put te binen.

⑤ Neidat de lead-out kabel is ferbûn mei de kontrôle switch, it is ferbûn oan de trije-fase Netzteil.

(4) Dingen om op te merken by ynstallaasje:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, please

Do not force the pump down to avoid damage to the submersible electric pump and the well.

2. By ynstallaasje moat in rubberen pad op 'e flange fan elke piip pleatst wurde en gelijkmatig oanskerpe.

3. As de wetterpomp yn 'e boarne ferlege wurdt, moat it yn' e midden fan 'e putpipe pleatst wurde om te foarkommen dat de pomp lang tsjin' e wellmuorre rint, wêrtroch't de pomp trillet en de motor sweep en brânt .

4. Bepale de djipte fan 'e wetterpomp nei de boaiem fan' e boarne neffens de streamende sân- en siltbetingsten fan 'e boarne. Begrave de pomp net yn 'e modder. De ôfstân fan 'e wetterpomp nei de boaiem fan' e put is oer it generaal net minder as 3 meter (sjoch figuer 2).

5. De wetteryngongsdjipte fan 'e wetterpomp moat net minder wêze as 1-1,5 meter fan it dynamyske wetterpeil nei it wetteryntreeknooppunt (sjoch figuer 2). Oars kinne de wetterpomplagers maklik skea wurde.

6. De lift fan 'e wetterpomp kin net te leech wêze. Oars, in poarte fentyl moat wurde ynstallearre op de wellhead wetter pipeline te kontrolearjen de pomp trochstreaming op de rated flow punt om foar te kommen dat de motor wurdt oerladen en útbaarnd fanwege grutte stream tariven.

7. As de wetterpomp rint, moat de wetterútfier kontinuële en sels wêze, de aktuele moat stabyl wêze (ûnder beoardielde wurkomstannichheden, oer it generaal net mear as 10% fan 'e nominearre aktuele), en der moat gjin trilling of lûd wêze. As der in abnormaliteit is, moat de masine wurde stoppe om de oarsaak te finen en it te eliminearjen.

8. By it ynstallearjen, betelje omtinken oan de ynstelling fan 'e motor grûndraad (sjoch figuer 2). As it wetter piip is in stielen piip, liedt it út de puthead clamp; as it wetter piip is in plestik piip, liedt it út 'e grûn mark fan' e elektryske pomp.

- 1.After de submersible pomp is ynstallearre, kontrolearje de isolaasje wjerstân en trije-fase conduction fan 'e skeakel wer, kontrolearje oft it ynstrumint en de ferbining fan' e start apparatuer binne ferkeard, as der gjin probleem, de proef masine kin wurde begûn, en observearje oft de yndikator lêzingen fan it ynstrumint heger wêze as de nominearre spanning en stroom oanjûn op it nammeplaat nei de start, en observearje oft de pomp hat lûd en trilling ferskynsel, en set yn wurking as alles is normaal.

- 2.Nei de earste operaasje fan 'e pomp foar fjouwer oeren moat de motor ôfsletten wurde om de thermyske isolaasjebestriding fluch te testen, en har wearde moat net minder wêze as 0,5 megaohm.

- 3.Nei't de pomp ôfsletten is, moat it nei fiif minuten begon wurde om te foarkommen dat de wetterkolom yn 'e piip folslein opnij wurdt en feroarsake in oerstallige motorstream en burnout.

- 4.Nei't de pomp yn 'e normale operaasje set is, om har libbenslibben te ferlingjen, is it nedich om te kontrolearjen oft de leveringsspanning, wurkstroom en isolaasjebestriding normaal regelmjittich binne. As de folgjende betingsten wurde fûn, moat de pomp daliks útskeakele wurde om problemen op te lossen.

- 1 In the rated condition, the current exceeds 20%.

- 2 De dynamyske wetterpeil sakket nei it wetter ynlaat seksje, wêrtroch intermitterende wetter.

- 3 De dompelpomp hat swiere trilling of lûd.

- 4 De oanbodspanning is leger dan 340 volt.

- 5 In lont is útbaarnd.

- 6 De wetterlieding piip is skansearre.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1.Untie the cable tie, remove the pipeline part, and remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product is an efficient and durable submersible electric pump, suitable for a variety of environments and applications.In order to ensure the long-term use and stable performance of the product, we suggest that users pay special attention to drying the water in the motor cavity in winter to avoid freezing; in addition, the cable is coiled and tied, and properly stored in an environment without corrosive substances and gases, with a temperature below 40 °C. If the product is not used for a long time, attention should be paid to rust prevention treatment to ensure the life cycle and performance of the product.Whether for industrial use or for home use, this submersible electric pump can provide you with reliable pump service.

-

- Impeller

- Shaft mouwe

- Rubber shaft sleeve

-

Segelring

01 Djippe boarne wetter yntak

02 Hege wetterfoarsjenning

03 berch wetterfoarsjenning

04 toer wetter

05 Agraryske yrrigaasje

06 tún yrrigaasje

07 rivier wetter yntak

08 húshâldlik wetter