Frequency conversion winding design, ensure the motor in 1HZ-50HZ long-term stable conversion operation. Energy saving, longer service life.

1, quvvat manbai: uch fazali AC 380V (tolerantlik + / - 5%), 50HZ (tolerantlik + / - 1%).

2, suv sifati:

(1) water temperature is not higher than 20 °C;

(2) qattiq aralashmalar miqdori (massa nisbati) 0,01% dan ko'p emas;

(3) PH qiymati (pH) 6,5-8,5;

(4) vodorod sulfidi miqdori 1,5 mg / L dan oshmaydi;

(5) xlorid ionining miqdori 400 mg / L dan oshmaydi.

3, vosita yopiq yoki suv bilan to'ldirilgan ho'l tuzilishga ega, ishlatishdan oldin suv ostidagi vosita bo'shlig'i toza suv bilan to'la bo'lishi kerak, noto'g'ri to'ldirilishining oldini olish uchun, keyin suv quyish, havo chiqarish murvatlarini torting, aks holda foydalanishga ruxsat etilmaydi.

4, suv osti nasosi to'liq suvga botirilishi kerak, sho'ng'in chuqurligi 70 m dan oshmasligi kerak, quduq ostidan suv osti nasosining pastki qismi 3 m dan kam emas.

5, quduq suvining oqimi suv osti nasosining suv chiqishi va uzluksiz ishlashiga javob berishi kerak, suv osti nasosining suv chiqishi nominal oqimning 0,7 - 1,2 barobarida nazorat qilinishi kerak.

6, quduq to'g'ri bo'lishi kerak, suv osti nasosini ishlatish yoki tushirish mumkin emas, faqat vertikal foydalanish.

7, suv osti nasosi talablarga muvofiq simi va tashqi ortiqcha yukdan himoya qilish moslamasi bilan mos kelishi kerak. 8, nasos suvsiz yuk sinov mashinasisiz qat'iyan man etiladi

| Model | Oqim (m3/soat) | Bosh (m) |

Rotating speed(change/point) | Suv nasosi(%) | Chiqish diametri (mm) |

Yaxshi qo'llanilishi mumkin diametri (mm) |

Baholangan quvvat (KVt) |

Rated voltage(V) | Ratedcurrent(A) | Motor samaradorligi (%) | power factorcosφ | Birlik Radial maksimal o'lcham (mm) |

Izoh | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125yuqorida | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125yuqorida | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125yuqorida | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125yuqorida | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125yuqorida | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125yuqorida | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125yuqorida | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125yuqorida | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

The well submersible pump is a pump suitable for clear water. It is strictly prohibited to dig new wells and pump out mud and sand. The voltage grade of the well pump is 380V/50HZ, and other voltage grades of the submersible motor need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protective device should be tripped in time. When installing and using the pump, it must be firmly grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power supply must be cut off before installing and maintaining the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing the motor, the inner cavity must be filled with distilled water or non-corrosive clean cold water, and the water injection/drainage bolts must be tightened. Fill the pump with water for ground test to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the direction is correct and consistent with the direction indication. Be sure to pay attention to safety when placing the pump upright to prevent overturning and causing injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump flow at low lift or excessive pull at high lift, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the insulation resistance between the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check the motor winding insulation, to see if it meets the requirements; if the pump storage temperature is below the freezing point, the water in the motor cavity should be discharged, so as to avoid the water in the motor cavity freezing and damaging the motor due to low temperature.

Mahsulotning asosiy xususiyatlari quyidagilardan iborat:

1.The motor is a water-loaded wet submersible three-phase asynchronous motor,and the motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference inside and outside the body caused by the temperature rise of the motor.

2.In order to prevent the sand particles in the well water from entering the motor,two oil seals are installed at the extension end of the motor shaft,and the sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from jumping when starting,the pump shaft is connected with the motor shaft through a coupling,and the thrust bearing is installed at the bottom of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The stator winding of the motor adopts high-quality submersible motor winding wire,with excellent insulation performance.

6.The pump is designed by computer CAD,with simple structure and excellent technical performance.

(1) O'rnatishdan oldin tayyorgarlik:

1. Suv osti nasosining qo'llanmada ko'rsatilgan foydalanish shartlari va ko'lamiga mos kelishini tekshiring.

2. Diametri suv osti nasosining maksimal tashqi diametriga teng bo'lgan og'ir obiektdan foydalanib, quduqning ichki diametri suv osti nasosiga mos kelishini o'lchang va quduq chuqurligi o'rnatish talablariga javob beradimi yoki yo'qligini o'lchang.

3. Quduq qudug'ining tozaligini va quduq suvining loyqaligini tekshiring. Suv osti elektr nasosiga muddatidan oldin shikast etkazmaslik uchun hech qachon suv osti nasosidan loy va qumli suvni yuvish uchun foydalanmang.

4. Quduq boshini o'rnatish qisqichining joylashuvi mos yoki yo'qligini va u butun qurilma sifatiga bardosh bera oladimi yoki yo'qligini tekshiring.

5. Qo'llanmadagi yig'ish sxemasiga muvofiq suv osti nasosi komponentlari to'liq va to'g'ri o'rnatilganligini tekshiring. Filtr ekranini olib tashlang va muftani egiluvchan aylanayotganligini ko'rish uchun aylantiring.

6. Suv vintini bo'shating va vosita bo'shlig'ini toza, korroziy bo'lmagan suv bilan to'ldiring (eslatma. uni to'ldirishni unutmang), so'ngra suv vintini torting. 12 soatlik suv quyishdan so'ng, 500V chayqash stoli bilan o'lchanganda, dvigatelning izolyatsiyaga chidamliligi 150M Q dan kam bo'lmasligi kerak.

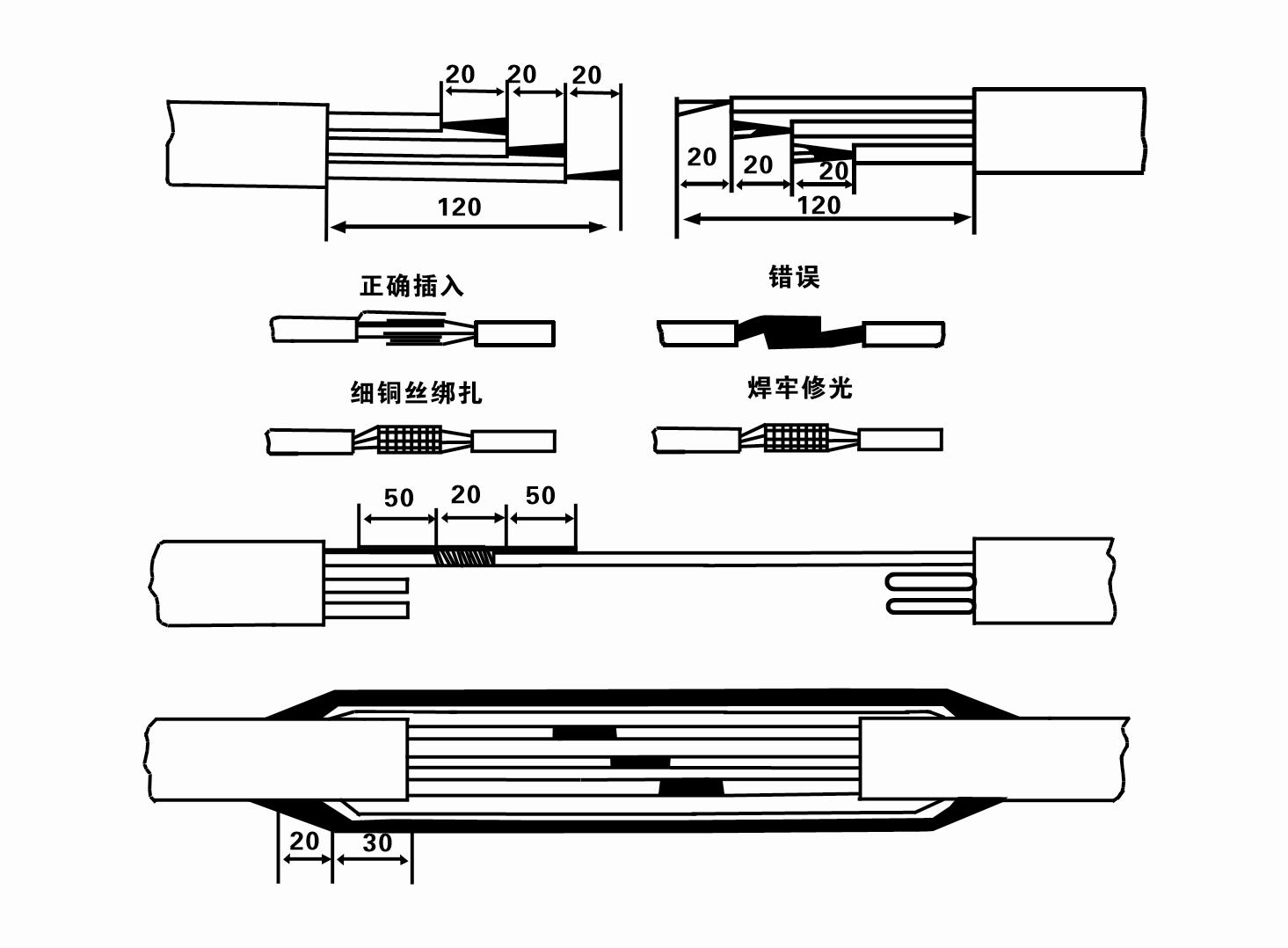

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.

After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

Qo'shilgan kabelni ulash jarayoni diagrammasi quyidagicha:

8. Multimetrdan foydalanib, uch fazali simlarning ulanganligini va shahar qarshiligining taxminan muvozanatlanganligini tekshiring.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and then

Pour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.

Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.

Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2) O'rnatish uskunalari va asboblari:

1. Ikki tonnadan ortiq yuk ko'tarish uchun bir juft zanjir.

2. Vertikal balandligi to'rt metrdan kam bo'lmagan tripod.

3. Bir tonnadan ortiq og'irlikni ko'tara oladigan ikkita osilgan arqon (sim arqonlari) (suv nasoslarining to'liq to'plamining og'irligini ko'tara oladi).

4. Ikki juft qisqichni (shponlarni) o'rnating.

5. Kalitlar, bolg'alar, tornavidalar, elektr asboblari va asboblari va boshqalar.

(3) Elektr nasosni o'rnatish:

1. Suv osti elektr nasosining o'rnatish sxemasi 2-rasmda ko'rsatilgan. Maxsus o'rnatish o'lchamlari 3-jadvalda "Suv ostidagi elektr nasosni o'rnatish o'lchamlari ro'yxati" da ko'rsatilgan.

2. Boshi 30 metrdan kam bo'lgan suv osti elektr nasoslari to'g'ridan-to'g'ri quduqqa shlanglar va sim arqonlar yoki butun mashinaning, suv quvurlarining va quvurlardagi suvning to'liq og'irligini ko'tara oladigan boshqa kanop arqonlari yordamida ko'tarilishi mumkin.

3. Boshi 30 metrdan ortiq bo‘lgan nasoslar po‘lat quvurlardan foydalanadi va o‘rnatish ketma-ketligi quyidagicha:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well until

Put the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flange

Put the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

③ Suv osti nasosini biroz ko'taring, suv nasosining yuqori uchidagi qisqichni echib oling, kabelni suv trubasiga plastik lenta bilan mahkam bog'lang va qisqich quduq boshiga o'rnatilguncha sekin bog'lang.

④Hamma suv quvurlarini quduqqa ulash uchun xuddi shu usuldan foydalaning.

⑤Chiqish kabeli boshqaruv kalitiga ulangandan so'ng, u uch fazali quvvat manbaiga ulanadi.

(4) O'rnatish vaqtida e'tiborga olish kerak bo'lgan narsalar:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, please

Do not force the pump down to avoid damage to the submersible electric pump and the well.

2. O'rnatish vaqtida har bir quvurning gardish qismida kauchuk yostiq qo'yilishi va bir tekis tortilishi kerak.

3. Suv nasosi quduqqa tushirilganda, nasosning quduq devoriga uzoq vaqt davomida ishlamasligi, nasosning tebranishi va dvigatelning supurib yonishiga olib kelishi uchun uni quduq trubasining o'rtasiga qo'yish kerak. .

4. Quduqning oqayotgan qum va loy sharoitiga qarab suv nasosining quduq tubiga chuqurligini aniqlang. Nasosni loyga ko'mmang. Suv nasosidan quduq tubigacha bo'lgan masofa odatda 3 metrdan kam emas (2-rasmga qarang).

5. Suv nasosining suvga kirish chuqurligi dinamik suv sathidan suv kirish tuguniga qadar 1-1,5 metrdan kam bo'lmasligi kerak (2-rasmga qarang). Aks holda, suv nasosining podshipniklari osongina shikastlanishi mumkin.

6. Suv nasosining ko'tarilishi juda past bo'lishi mumkin emas. Aks holda, katta oqim tezligi tufayli dvigatelning haddan tashqari yuklanishi va yonib ketishining oldini olish uchun nominal oqim nuqtasida nasos oqimini nazorat qilish uchun quduq bo'yidagi suv quvur liniyasiga eshik klapanini o'rnatish kerak.

7. Suv pompasi ishlayotganida, suv chiqishi uzluksiz va bir tekis bo'lishi kerak, oqim barqaror bo'lishi kerak (nominal ish sharoitida, odatda nominal oqimning 10% dan ko'p bo'lmagan) va tebranish yoki shovqin bo'lmasligi kerak. Agar biron bir anormallik bo'lsa, sababni aniqlash va uni bartaraf etish uchun mashinani to'xtatish kerak.

8. O'rnatishda vosita topraklama simini sozlashga e'tibor bering (2-rasmga qarang). Suv trubkasi po'lat quvur bo'lsa, uni quduqning qisqichidan olib boring; suv trubkasi plastik quvur bo'lsa, uni elektr nasosning topraklama belgisidan olib boring.

- 1. Suv osti nasosi o'rnatilgandan so'ng, kalitdan izolyatsiya qarshiligi va uch fazali o'tkazuvchanlikni yana tekshiring, asbob va ishga tushirish uskunasining ulanishi noto'g'ri yoki yo'qligini tekshiring, agar muammo bo'lmasa, sinov mashinasini ishga tushirish mumkin, va ishga tushirilgandan so'ng asbobning indikator ko'rsatkichlari nominal kuchlanish va oqimdan oshib ketishini kuzatib boring va nasosning shovqin va tebranish hodisasi bor-yo'qligini kuzatib boring va agar hamma narsa normal bo'lsa, ishga tushiring.

- 2.To'rt soat davomida nasosning birinchi ishidan so'ng, issiqlik izolyatsiyasi qarshiligini tezda sinab ko'rish uchun vosita o'chirilishi kerak va uning qiymati 0,5 megaohmdan kam bo'lmasligi kerak.

- 3.Nasos o'chirilgandan so'ng, quvurdagi suv ustunining to'liq qayta oqimiga yo'l qo'ymaslik va haddan tashqari vosita oqimi va yonishini oldini olish uchun uni besh daqiqadan so'ng ishga tushirish kerak.

- 4.Nasos normal ishga tushirilgandan so'ng, uning ishlash muddatini uzaytirish uchun muntazam ravishda besleme zo'riqishida, ish oqimi va izolyatsiya qarshiligi normal yoki yo'qligini tekshirish kerak. Agar quyidagi shartlar aniqlansa, muammolarni bartaraf etish uchun nasosni darhol o'chirib qo'yish kerak.

- 1 In the rated condition, the current exceeds 20%.

- 2 Dinamik suv sathi suv kirish qismiga tushib, suvning vaqti-vaqti bilan paydo bo'lishiga olib keladi.

- 3 Suv osti nasosi kuchli tebranish yoki shovqinga ega.

- 4 Ta'minot kuchlanishi 340 voltdan past.

- 5 Sug'urta yonib ketgan.

- 6 Suv ta'minoti trubkasi shikastlangan.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1.Untie the cable tie, remove the pipeline part, and remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product is an efficient and durable submersible electric pump, suitable for a variety of environments and applications.In order to ensure the long-term use and stable performance of the product, we suggest that users pay special attention to drying the water in the motor cavity in winter to avoid freezing; in addition, the cable is coiled and tied, and properly stored in an environment without corrosive substances and gases, with a temperature below 40 °C. If the product is not used for a long time, attention should be paid to rust prevention treatment to ensure the life cycle and performance of the product.Whether for industrial use or for home use, this submersible electric pump can provide you with reliable pump service.

-

- Pervanel

- Mil yengi

- Kauchuk mil yengi

-

Muhrlash halqasi

01 Chuqur quduqdan suv olish

02 Ko'p qavatli suv ta'minoti

03 tog 'suv ta'minoti

04 minora suvi

05 Qishloq xo'jaligini sug'orish

06 bog'ni sug'orish

07 daryo suv olish

08 maishiy suv