Frequency conversion winding design, ensure the motor in 1HZ-50HZ long-term stable conversion operation. Energy saving, longer service life.

1, tuʻuina atu eletise: tolu-vaega AC 380V (faʻapalepale + / - 5%), 50HZ (faʻapalepale + / - 1%).

2, lelei vai:

(1) water temperature is not higher than 20 °C;

(2) faʻamaʻi eleelea faʻamaʻi (fuainumera tele) e le sili atu i le 0.01%;

(3) PH tau (pH) 6.5-8.5;

(4) e le sili atu i le 1.5mg/L mea e maua i le hydrogen sulfide;

(5) e le sili atu i le 400mg/L le mea o iai ion chloride.

3, o le afi tapuni poʻo le faʻatumu vai susu fausaga, aʻo leʻi faʻaaogaina le vaʻa afi afi e tatau ona tumu i vai mama, e puipuia ai le tumu sese, ona faʻamalosi lea o le tui vai, faʻamau faʻamalolo ea, a le o lea e le faʻatagaina e faʻaaoga.

4, e tatau ona goto uma i totonu o le vai, o le loloto o le maulu e le sili atu nai lo le 70m, o le pito i lalo ole pamu mai le pito i lalo ole vaieli e le itiiti ifo i le 3m.

5, e tatau ona mafai e le vai lelei ona faʻafeiloaʻi le gaosiga o le pamu vai ma faʻaauau pea le faʻagaioiga, e tatau ona pulea le gaosiga o le suavai i le 0.7 - 1.2 taimi o le tafe fua.

6, e tatau ona saʻo le vaieli, e le mafai ona faʻaaogaina pe lafoai le pamu faʻafefe, naʻo le faʻaogaina i luga.

7, o le pamu submersible e tatau ona faʻafetaui ma le uaea e tusa ai ma manaʻoga, ma le masini puipuia le mamafa i fafo. 8, o le pamu e matua faʻasaina e aunoa ma se vai e leai se uta masini suʻega

| Fa'ata'ita'iga | tafe (m3/h) | Ulu (m) |

Rotating speed(change/point) | pamu vai(%) | Outlet lautele (mm) |

Fa'aoga lelei lautele(mm) |

Fa'atauaina malosi(KW) |

Rated voltage(V) | Ratedcurrent(A) | Malosiaga tau afi (%) | power factorcosφ | Vaega Ole tele ole tele (mm) |

Fa'amatalaga | |||||||||

| 125QJ5-34 | 5 | 34 | 2850 | 53 | 40 | 125luga | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ5-51 | 51 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ5-68 | 68 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ5-85 | 85 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ5-102 | 102 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ5-119 | 119 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-24 | 10 | 24 | 2850 | 60 | 50 | 125luga | 1.5 | 380 | 4.23 | 70.0 | 0.77 | 118 | ||||||||||

| 125QJ10-32 | 32 | 2.2 | 6.03 | 72.0 | 0.77 | |||||||||||||||||

| 125QJ10-48 | 48 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ10-56 | 56 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ10-72 | 72 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-80 | 80 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ10-104 | 104 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ10-120 | 10 | 120 | 2850 | 60 | 50 | 125luga | 7.5 | 380 | 19.0 | 76.0 | 0.79 | 118 | ||||||||||

| 125QJ10-136 | 136 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ15-36 | 15 | 36 | 2850 | 63 | 50 | 125luga | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ15-39 | 39 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ15-46 | 46 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-52 | 52 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ15-59 | 59 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-65 | 65 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ15-78 | 78 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-91 | 91 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ15-104 | 104 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ20-16 | 20 | 16 | 2850 | 64 | 50 | 125luga | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ20-24 | 24 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ20-32 | 32 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-40 | 40 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ20-48 | 48 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-56 | 56 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ20-64 | 64 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-72 | 72 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ20-80 | 80 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ25-12 | 25 | 12 | 2850 | 64 | 65 | 125luga | 2.2 | 380 | 6.03 | 72.0 | 0.77 | 118 | ||||||||||

| 125QJ25-18 | 18 | 3 | 8.01 | 73.0 | 0.78 | |||||||||||||||||

| 125QJ25-24 | 24 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-30 | 30 | 4 | 10.53 | 74.0 | 0.78 | |||||||||||||||||

| 125QJ25-36 | 36 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ25-48 | 48 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ25-60 | 60 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ32-24 | 32 | 24 | 2850 | 64 | 80 | 125luga | 4 | 380 | 10.53 | 74.0 | 0.78 | 118 | ||||||||||

| 125QJ32-30 | 30 | 5.5 | 14.1 | 75.0 | 0.79 | |||||||||||||||||

| 125QJ32-42 | 42 | 7.5 | 19.0 | 76.0 | 0.79 | |||||||||||||||||

| 125QJ32-54 | 54 | 9.2 | 22.7 | 77.0 | 0.8 | |||||||||||||||||

| 125QJ5-240 | 5 | 240 | 2850 | 40 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ5-280 | 280 | 13 | 30.87 | |||||||||||||||||||

| 125QJ5-320 | 320 | 15 | 35.62 | |||||||||||||||||||

| 125QJ10-180 | 10 | 180 | 2850 | 50 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ10-210 | 210 | 13 | 30.87 | |||||||||||||||||||

| 125QJ10-240 | 240 | 15 | 35.62 | |||||||||||||||||||

| 125QJ15-120 | 15 | 120 | 2850 | 50 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ15-142 | 142 | 13 | 30.87 | |||||||||||||||||||

| 125QJ15-162 | 162 | 15 | 35.62 | |||||||||||||||||||

| 125QJ20-100 | 20 | 100 | 2850 | 50 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ20-120 | 120 | 13 | 30.87 | |||||||||||||||||||

| 125QJ20-136 | 136 | 15 | 35.62 | |||||||||||||||||||

| 125QJ25-82 | 25 | 82 | 2850 | 65 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ25-97 | 97 | 13 | 30.87 | |||||||||||||||||||

| 125QJ25-110 | 110 | 15 | 35.62 | |||||||||||||||||||

| 125QJ32-68 | 32 | 68 | 2850 | 80 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ32-80 | 80 | 13 | 30.87 | |||||||||||||||||||

| 125QJ32-92 | 92 | 15 | 35.62 | |||||||||||||||||||

| 125QJ40-46 | 40 | 46 | 2850 | 80 | 125luga | 11 | 380 | 26.28 | 118 | |||||||||||||

| 125QJ40-54 | 54 | 13 | 30.87 | |||||||||||||||||||

| 125QJ40-62 | 62 | 15 | 35.62 | |||||||||||||||||||

The well submersible pump is a pump suitable for clear water. It is strictly prohibited to dig new wells and pump out mud and sand. The voltage grade of the well pump is 380V/50HZ, and other voltage grades of the submersible motor need to be customized. Underground cables must be waterproof cables and must be equipped with starting equipment, such as distribution box, etc. The starting equipment should have common motor comprehensive protection functions, such as short circuit overload protection, phase loss protection, undervoltage protection, grounding protection and idling protection, etc. In abnormal cases, the protective device should be tripped in time. When installing and using the pump, it must be firmly grounded. It is prohibited to push and pull the switch when the hands and feet are wet. The power supply must be cut off before installing and maintaining the pump. An obvious "anti-electric shock" sign must be set up where the pump is used. Before going down the well or installing the motor, the inner cavity must be filled with distilled water or non-corrosive clean cold water, and the water injection/drainage bolts must be tightened. Fill the pump with water for ground test to lubricate the rubber bearings. The instant start time shall not exceed one second to check whether the direction is correct and consistent with the direction indication. Be sure to pay attention to safety when placing the pump upright to prevent overturning and causing injury. Strictly in accordance with the provisions of the pump lift and flow range of use, to prevent the pump flow at low lift or excessive pull at high lift, resulting in extreme wear of thrust bearings and other components, resulting in motor overload burn. After the pump into the well, the insulation resistance between the motor and the ground shall be measured, which shall not be less than 100MΩ. After the start, observe the voltage and current regularly, and check the motor winding insulation, to see if it meets the requirements; if the pump storage temperature is below the freezing point, the water in the motor cavity should be discharged, so as to avoid the water in the motor cavity freezing and damaging the motor due to low temperature.

O uiga autu o le oloa e aofia ai:

1.The motor is a water-loaded wet submersible three-phase asynchronous motor,and the motor cavity is filled with clean water for cooling the motor and lubricating the bearing.The regulating diaphragm at the bottom of the motor is used to adjust the expansion and contraction pressure difference inside and outside the body caused by the temperature rise of the motor.

2.In order to prevent the sand particles in the well water from entering the motor,two oil seals are installed at the extension end of the motor shaft,and the sand ring is installed to form a sand prevention structure.

3.In order to prevent the pump shaft from jumping when starting,the pump shaft is connected with the motor shaft through a coupling,and the thrust bearing is installed at the bottom of the motor.

4.The lubrication of the motor and the pump bearing is water lubrication.

5.The stator winding of the motor adopts high-quality submersible motor winding wire,with excellent insulation performance.

6.The pump is designed by computer CAD,with simple structure and excellent technical performance.

(1) Sauniuniga aʻo leʻi faʻapipiʻiina:

1. Siaki pe fetaui le pamu fa'asusu i le fa'aogaina ma le lautele o lo'o fa'ailoa mai ile tusi lesona.

2. Fa'aaogaina o se obiect mamafa ma le lautele e tutusa ma le maualuga pito i fafo o le pamu fa'asusu, fua pe mafai e le inneldiameter o le vaieli ona ofi le pamu fa'asusu, ma fua pe o le loloto o le vai e fetaui ma mana'oga fa'apipi'i.

3. Siaki pe mama le vaieli ma pe o le vaieli e pala. 'Aua ne'i fa'aogaina se pamu eletise e fa'ato'ilaloina e fufulu ai le palapala ma le oneone o le pa'u welor e 'alofia ai le vave fa'aleagaina o le pamu eletise fa'alalo.

4. Siaki pe talafeagai le tulaga o le faʻapipiʻi welhead faʻapipiʻi ma pe mafai ona tatalia le tulaga o le iunite atoa

5. Siaki pe ua mae'a ma fa'apipi'i lelei vaega o pamu fa'asusu e tusa ai ma le fa'ata'otoga o lo'o i totonu o le tusi lesona.

6. Tatala le fa'avili vai ma fa'atumu le oga o le afi i vai mama, e le pala (matau. ia mautinoa e fa'atutu i luga), ona fa'amau lea o le fa'asuavai. A maeʻa le 12 itula o le tui vai, e le tatau ona itiiti ifo i le 150M Q le teteʻe o le afi ile 500V pe a fua ile laulau lulu 500V.

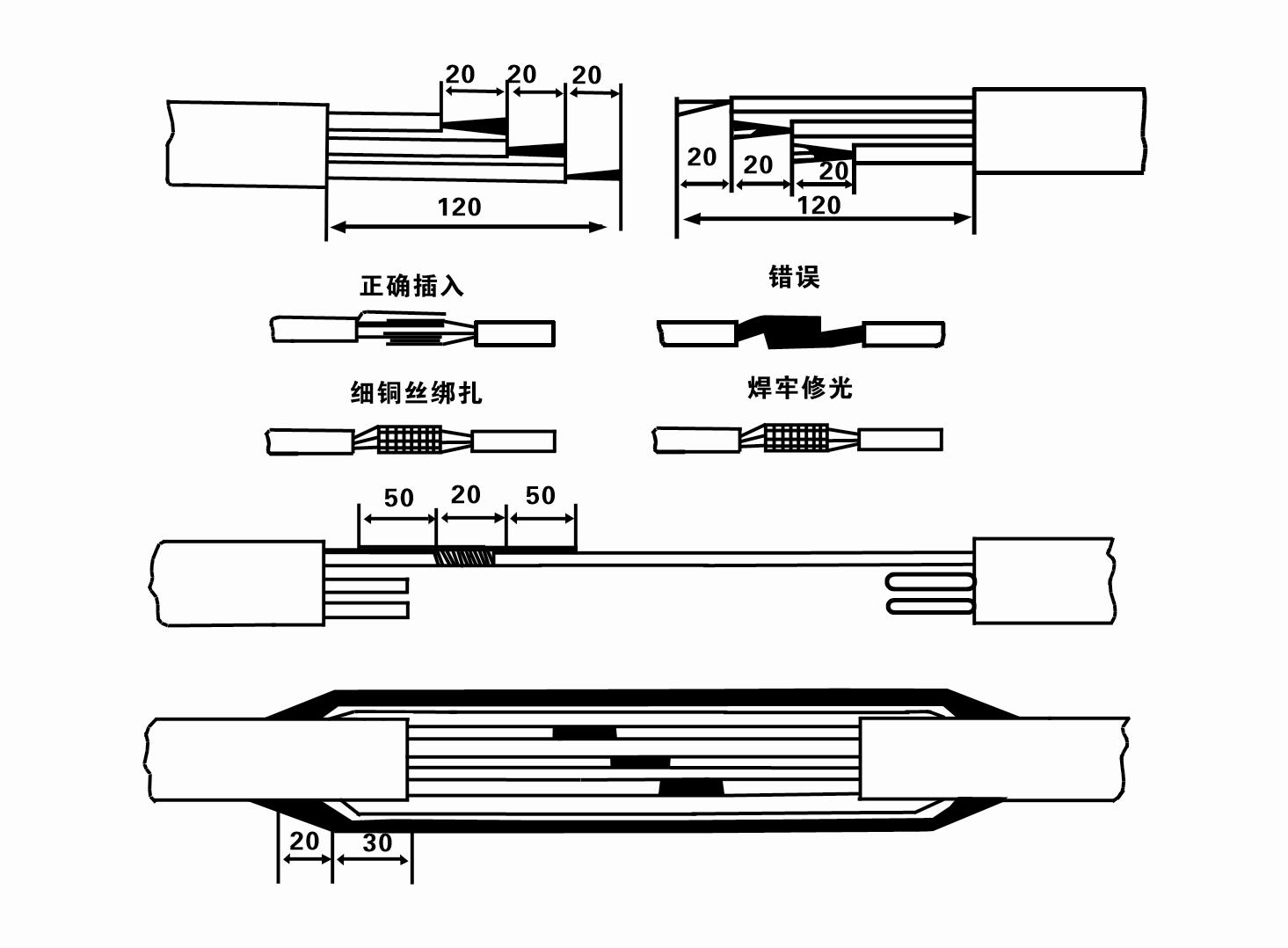

7. Cable joint, cut off a 120mm rubber sleeve from one end of the outgoing cable and the matching cable with an electrician's knifethen stagger the length of the three core wires in a stepped shape, peel off a 20mm copper core, scrape of the oxide layer on theoutside of the copper wire with a knife or sand cloth, and insert the two connected wire ends in palirs.

After tying the layer tightly with fine copper wire, solder it thoroughly and firmly, and sand of any. burrs on the surface. Then, forthe three joints, use polyvester insulation tape to wrap them in a semi stacked manner for three lavers. Wrap the two ends of thewrapping layer tightywith nyion thread,and then use a semi stacked method to wrap the tape for three layers. Wrap the outellayer with high-pressure insulation tape for three layers. Finally, fold the threestrands together and repeatedly wrap them for fivelayers with high-pressure tape. Each layer must be tightly tied, and the interlayer joints must be tight and fimm to prevent water frompenetrating and damaging the insulation, After wrapping, soak in water at room temperature of 20 ’c for 12 hours, and measurethe insulation resistance with a shaking table, which should not be less than 100M Ω

O le fa'apipi'i fa'apipi'i fa'asologa o fa'agasologa o uaea e fa'apea:

8. Fa'aaoga se multimeter e siaki ai pe o feso'ota'i laina e tolu-vaega ma pe fa'atatau i le paleni DC.

9. Check whether the circuit and transformer capacity are overloaded, and then connect the overload protection switch or starting equipment. See Table 2 for specific models, and then

Pour a bucket of water into the water pump from the water pump outlet to lubricate the rubber bearings in the pump, and then place the submersible electric pump upright and steady.

Start (no more than one second) and check whether the steering direction is consistent with the steering sign. If not, swap any two connectors of the three-phase cable.

Then install the filter and prepare to go down the well. If used in special occasions (such as ditches, ditches, rivers, ponds, ponds, etc.), the electric pump must be reliably grounded.

(2) Fa'apipi'i meafaigaluega ma meafaigaluega:

1. Tasi le pea o filifili si'i mo le sili atu i le lua tone.

2. O se tripod ma le maualuga tuusaʻo e le itiiti ifo i le fa mita.

3. E lua maea tautau (uaea uaea) e mafai ona tauave le mamafa e sili atu ma le tasi tone (e mafai ona tauave le mamafa o se seti atoa o pamu vai).

4. Fa'apipi'i ni paipa se lua (splints).

5. Tu'u, samala, sikuli, meafaigaluega eletise ma meafaigaluega, ma isi.

(3) Fa'apipi'i pamu eletise:

1. O le faʻapipiʻiina o le faʻapipiʻiina o le pamu eletise o loʻo faʻaalia i le Ata 2. O faʻamaufaʻailoga faʻapipiʻi faʻapitoa o loʻo faʻaalia i le Laulau 3 "Lisi o Fua Faʻapipiʻi o le Pump Eletise Submersible".

2. O pamu eletise e mafai ona faʻafefeteina ma le ulu e itiiti ifo i le 30 mita e mafai ona sisi saʻo i totonu o le vaieli e faʻaaoga ai faʻagaau ma maea uaea poʻo isi maea hemp e mafai ona tauaveina le mamafa atoa o le masini, paipa vai, ma vai i totonu o paipa.

3. O pamu ma le ulu e sili atu i le 30 mita e faʻaaogaina paipa uʻamea, ma o le faʻasologa faʻapipiʻi e faʻapea:

①Use a clamp to clamp the upper end of the water pump part (the motor and water pump have been connected at this time), lift it with a hanging chain, and slowly tie it into the well until

Put the clamp on the wellhead and remove the hanging chain.

② Use another pair of clamps to clamp a pipe, lift it with a hanging chain 15 cm away from the flange, and lower it slowly. Between pipe flange and pump flange

Put the rubber pad in place and tighten the pipe and pump evenly with bolts, nuts and spring washers.

③ Si'i teisi le pamu vai, aveese le pipii i le pito pito i luga o le pamu vai, nonoa le uaea i le paipa vai i se pa'u palasitika, ma nonoa malie i lalo seia tu'u le pipii i le ulu vaieli.

④ Fa'aaoga le auala lava e tasi e nonoa uma ai paipa vai i totonu o le vaieli.

⑤A maeʻa ona fesoʻotaʻi le uaea taʻitaʻia i le ki faʻatonutonu, e faʻafesoʻotaʻi i le sapalai eletise tolu-vaega.

(4) Mea e matauina i le taimi o le faʻapipiʻiina:

1. If a jamming phenomenon is found during the pumping process, turn or pull the water pipe to overcome the jamming point. If various measures still do not work, please

Do not force the pump down to avoid damage to the submersible electric pump and the well.

2. I le taimi o le faʻapipiʻiina, e tatau ona tuʻu se paʻu paʻu i le flange o paipa taʻitasi ma faʻapipiʻi tutusa.

3. A tuu i lalo le pamu vai i totonu o le vaieli, e tatau ona tuʻu i le ogatotonu o le paipa vaieli e puipuia ai le pamu mai le faʻasaga i le puipui o le vaieli mo se taimi umi, ma mafua ai ona tete le pamu ma salu ma mu le afi. .

4. Fuafua le loloto o le pamu vai i le pito i lalo o le vaieli e tusa ai ma tulaga o le tafe o le oneone ma le palapala o le vaieli. Aua le tanumia le pamu i le palapala. O le mamao mai le pamu vai i le pito i lalo o le vaieli e masani lava e le itiiti ifo i le 3 mita (silasila i le Ata 2).

5. O le loloto o le vai o le pamu vai e tatau ona le itiiti ifo i le 1-1.5 mita mai le maualuga o le vai i le node o le vai (silasila i le Ata 2). A leai, e mafai ona faigofie ona faʻaleagaina le paʻu vai.

6. O le si'itia o le pamu vai e le mafai ona maualalo tele. A leai, e tatau ona fa'apipi'i se alavai faitoto'a i luga o le paipa vai e fa'atonutonu ai le tafe o le pamu i le nofoaga fa'atatau e puipuia ai le afi mai le mamafa ma mu ona o le tele o tafega.

7. A oʻo ina tamoʻe le pamu vai, e tatau ona faʻaauau pea le gaosiga o le vai ma e oʻo lava, o le taimi nei e tatau ona mautu (i lalo o tulaga faigaluega faʻatulagaina, e masani lava e le sili atu i le 10% o le taimi nei faʻamauina), ma e le tatau ona i ai se vibration poʻo le pisa. Afai ei ai se faaletonu, e tatau ona taofi le masini e suʻe le mafuaʻaga ma faʻaumatia.

8. A faʻapipiʻi, faʻalogo lelei i le faʻatulagaina o le uaea faʻavae afi (silasila i le Ata 2). Afai o le paipa vai o se paipa u'amea, ta'ita'i mai le fa'amau o le vaieli; pe a avea le paipa vai o se paipa palasitika, taʻitaʻia mai le faʻailoga o le pamu eletise.

- 1. A maeʻa ona faʻapipiʻi le pamu submersible, siaki le faʻaogaina o le insulation ma le tolu-vaega faʻatautaia mai le ki, siaki pe sese le meafaigaluega ma le fesoʻotaʻiga o mea amata, pe a leai se faʻafitauli, e mafai ona amata le masini faʻataʻitaʻiga, ma mataʻituina pe sili atu le fua faʻatatau o le meafaifaʻaili i le voltage faʻamaonia ma le taimi nei o loʻo faʻamaonia i luga o le nameplate pe a maeʻa le amataga, ma mataʻituina pe o le pamu o loʻo i ai le pisapisao ma le vibration, ma faʻaogaina pe a masani mea uma.

- 2. A maeʻa le faʻaogaina muamua o le pamu mo le fa itula, e tatau ona tapuni le afi e faʻataʻitaʻi vave le faʻaogaina o le vevela, ma o lona tau e le tatau ona itiiti ifo i le 0.5 megaohm.

- 3. A maeʻa ona tapunia le pamu, e tatau ona amata pe a uma le lima minute e puipuia ai le koluma vai i totonu o le paipa mai le toe faʻaleleia atoatoa ma mafua ai le tele o le afi afi ma le susunuina.

- 4. A maeʻa ona tuʻuina le pamu i le gaioiga masani, ina ia faʻaumiina lona ola tautua, e tatau ona siaki pe o le voltage tuʻuina atu, galue i le taimi nei ma le faʻaogaina o le insulation e masani lava. Afai e maua tulaga nei, e tatau ona tapuni vave le pamu e foia faafitauli.

- 1 In the rated condition, the current exceeds 20%.

- 2 O le maualuga o le vai e pa'ū i le vaega o le vai, ma mafua ai le vai vavave.

- 3 O le pamu fa'afefeteina e tele le tetete po'o le pisa.

- 4 E maualalo ifo i le 340 volts le voltage sapalai.

- 5 Ua mu se fuse.

- 6 Ua leaga le paipa vai.

- 7 The motor's thermal insulation resistance is lower than 0.5 megaohm.

- Unit disassembly:

- 1.Untie the cable tie, remove the pipeline part, and remove the wire plate.

- 2.screw down the water bolt, put the water in the motor chamber.

- 3.remove the filter, loose the fixed screw on the coupling to fix the motor shaft.

- 4.screw down the bolt connecting the water inlet section with the motor, and separate the pump from the motor (pay attention to the unit cushion when separating, to prevent the bending of the pump shaft)

- 5.the disassembly sequence of the pump is: (see figure 1) water inlet section, impeller, diversion shell, impeller...... check valve body, when removing the impeller, use special tools to loosen the conical sleeve of the fixed impeller first, and avoid bending and bruising the pump shaft in the process of disassembly.

- 6.the disassembly process of the motor is: (see figure 1) place the motor on the platform, and remove the nuts, base, shaft head locking nut, thrust plate, key, lower guide bearing seat and double head bolt from the bottom of the motor in turn, and then take out the rotor (pay attention not to damage the wire package) and finally remove the connecting section and upper guide bearing seat.

- 7.unit assembly: before assembly, the rust and dirt of the parts should be cleaned, and the mating surface and fasteners coated with sealant, and then assembled in the opposite order of disassembly (the motor shaft moves up and down after assembly for about one millimeter), after assembly, the coupling should be flexible, and then the filter screen test machine. Submersible pumps shall be taken out of the well for dismantling and maintenance according to Article 5 after a year of operation, or less than a year of operation but two years of diving time, and the worn parts shall be replaced.

This product is an efficient and durable submersible electric pump, suitable for a variety of environments and applications.In order to ensure the long-term use and stable performance of the product, we suggest that users pay special attention to drying the water in the motor cavity in winter to avoid freezing; in addition, the cable is coiled and tied, and properly stored in an environment without corrosive substances and gases, with a temperature below 40 °C. If the product is not used for a long time, attention should be paid to rust prevention treatment to ensure the life cycle and performance of the product.Whether for industrial use or for home use, this submersible electric pump can provide you with reliable pump service.

-

- Fa'aoso

- lima lima

- lima o le pa'u pa'u

-

Mama fa'amau

01 Vaivai loloto

02 Suavai maualuga

03 vai mai mauga

04 vai olo

05 Fa'asusu fa'ato'aga

06 fa'asusuina o togalaau

07 vai inu vai

08 vai aiga